There are many kinds of materials for making cable supports. At present, metal Angle iron cable supports, cement cable supports and polymer composite cable supports are widely used. For a long time, the power system and the public utility sector using metal Angle iron, aluminum alloy or cement cable bracket laying cable more.

Traditional material of cable support, performance limitation due to material itself, has been in use there are many defects, such as the traditional cable metal stents in harsh environments prone to corrosion, short service life, such as subway, tunnel, chemical industry, such as wet or damp coastal salt fog, use metal stent is easily corroded, the high cost of facilities maintenance, and short service life.

With the need of electric power engineering construction, especially the cable into ground project in the transformation of power grid in large and medium cities, there is an urgent need for a new generation of cable supports with excellent performance, long service life and more efficient, safe and reliable cable laying.

SMC mold has excellent electrical insulation, arc resistance, so it has been widely used in the power system: motor commutator, terminal board, arc cover, cable distribution box shell, terminal distributor, cable bracket and other equipment are used in SMC. The research shows that the SMC polymer composite power cable bracket is the most superior one.

SMC mold has the following characteristics:

①High strength, light weight, weight is only 1/4 of steel, about 1/10 of concrete pipe, convenient transportation, convenient construction.

②The surface of the product is smooth and the friction coefficient is small, which does not damage the cable.

③The whole insulation, no electrical corrosion, can prevent eddy current.

④Good water resistance, can be used in wet environment or water for a long time.

⑤ Heat resistance, cold resistance, fire performance is excellent, can be used at -50℃-130℃.

⑥ Anti-corrosion, no rust, long service life, maintenance free.

The material has no recycling value, can eliminate the problem of theft.

⑧ Good insulation performance, no grounding, can reduce installation workload, save installation cost.

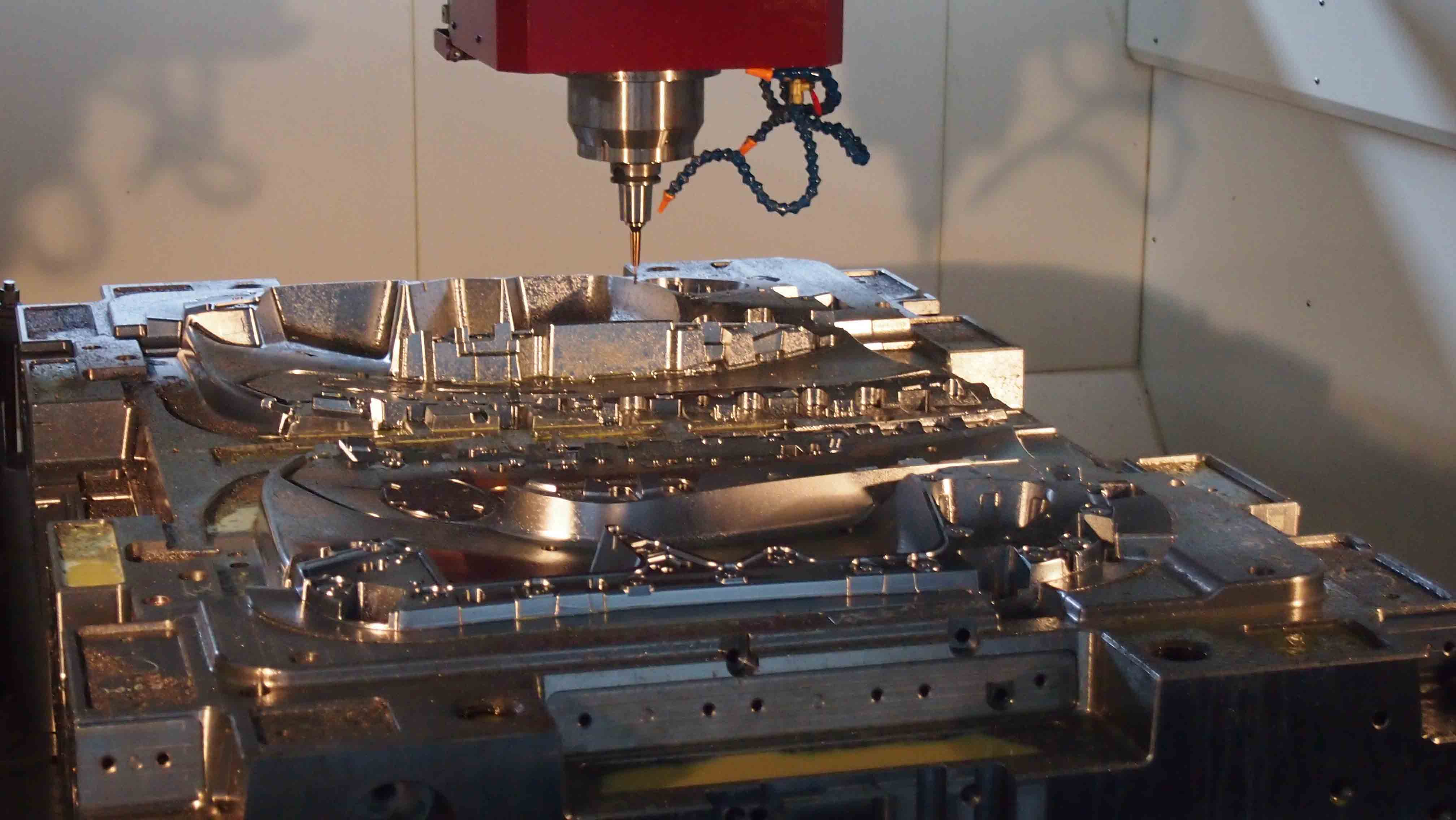

SMC cable bracket mold features:

SMC cable bracket mould can be widely used for laying power cables, control cables and communication cables in cable trench, cable tunnel, cable pipe working well and cable half layer.

① High strength and light weight. SMC polymer composites are mainly composed of glass fiber and thermosetting resin, which can strengthen and transfer load. The tensile strength of glass fiber is very high (3450MPa), and its content, length and laying form determine the strength of bracket products. SMC mold strength can be in the range of 30 ~ 1000MPa. Therefore, the amount, length and laying form of glass fiber can be designed according to the force, output, production technology and price bearing capacity of products.

② No creep. The rigidity of SMC cable bracket mold is twice that of glass fiber reinforced nylon bracket produced by some foreign companies. It does not deform even under long-term load.

③ Strong fire performance. Oxygen index is an important means to evaluate cable fire protection products. Oxygen index refers to the fire resistance of a fireproof product under maximum oxygen conditions. The use in engineering is determined according to the intensity of combustion. For example, under the condition of 30 cables, if cable ignition accident occurs, high temperature heat accumulation above 500℃ can be formed within 4 minutes, which leads to delayed ignition of cables along the direction. The more cables there are, the more combustible mass there is. The oxygen index of SMC cable bracket mold is greater than or equal to 70%. In line with the fire low smoke, no halogen, non-toxic safety requirements, fire performance is strong.

④ corrosion resistance. SMC cable bracket mould has good corrosion resistance, especially suitable for use in wet, salt fog, acid and weak alkali environment.

⑤Good insulation performance. Insulation properties can be adjusted according to the requirements of use. Generally, the insulation resistance is greater than or equal to 1.0 x 1012 ω.

⑥ Easy to use. The embedded bracket can be directly embedded into the wall of the cable trench, the screw hole bracket has been reserved for installation, directly fixed with screws, installation and maintenance is very convenient. Cable bracket bracket adopts circular arc smooth surface, no barb and parting line, will not strain the cable, and can reduce the labor intensity of workers.

⑦ Long service life. General service life: indoor more than 20 years, underground more than 50 years; Service life of aging resistant type: outdoor 20 years.

⑧ good economic benefits. SMC cable bracket mold integral structure, simplify the installation process, improve the installation efficiency, shorten the engineering period, reduce the cost of engineering and its strong corrosion resistance, no maintenance and replacement characteristics, its advantages are obvious.

MDC is a professional supplier of SMC mould, producing and manufacturing SMC cable bracket mould, experienced, deeply loved by customers, if you have demand, please contact us!