As the most advanced and popular equipment shell manufacturing material in the world, SMC composite material has incomparable advantages over other non-metallic materials and metal materials.

Composite materials and metals, polymers, and ceramics are called the four major materials.

SMC material itself has good anti-aging properties. SMC is currently the mainstream material on the market. SMC composite materials can effectively resist the corrosion of seawater, gasoline, alcohol, electrolytic salts, acetic acid, hydrochloric acid, sodium-potassium compounds, urine, asphalt, various acid-alkaline soils and acid rain.

Among non-metallic materials, fiber-reinforced polyester materials have excellent anti-aging properties. Anti-aging performance tests show that the maximum degree of surface aging is small in different locations and climatic zones, so there is no significant effect on the mechanical properties of the product.

SMC material has good impact toughness. Therefore, it is suitable for the entire bathroom, the entire bathroom overhead structure layer, and an air layer is formed between the waterproof chassis and the ground, which can effectively buffer the impact. At the same time, with thermal insulation properties, the skin feels warm and insulated in winter and summer.

SMC material has high plasticity. SMC can be used in a variety of applications according to the design requirements of structural design and surface texture design (leather texture, wood, stone, sand surface, smooth surface and other surface textures), common applications are leather textures, such as aircraft warehouse boards, mobile Auto warehouse interior panels and auto warehouse panels mainly choose texture, which is not only durable or durable, but with the continuous application of new technologies, the surface’s anti-scratch, anti-static, and easy-to-clean properties are greatly improved.

Products made of SMC materials are green and environmentally friendly. SMC is lightweight, durable and has a long (50) year lifespan. At the same time, the formaldehyde emission standard of SMC material reaches E0 standard level, contains no halogen, and has no harmful substances to the human body.

So, how is SMC material made into SMC mould?

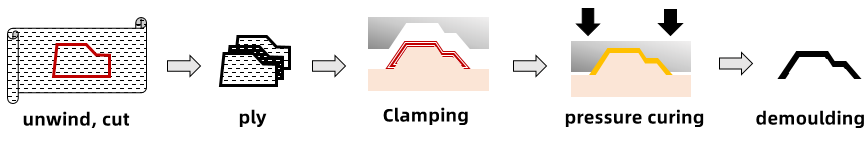

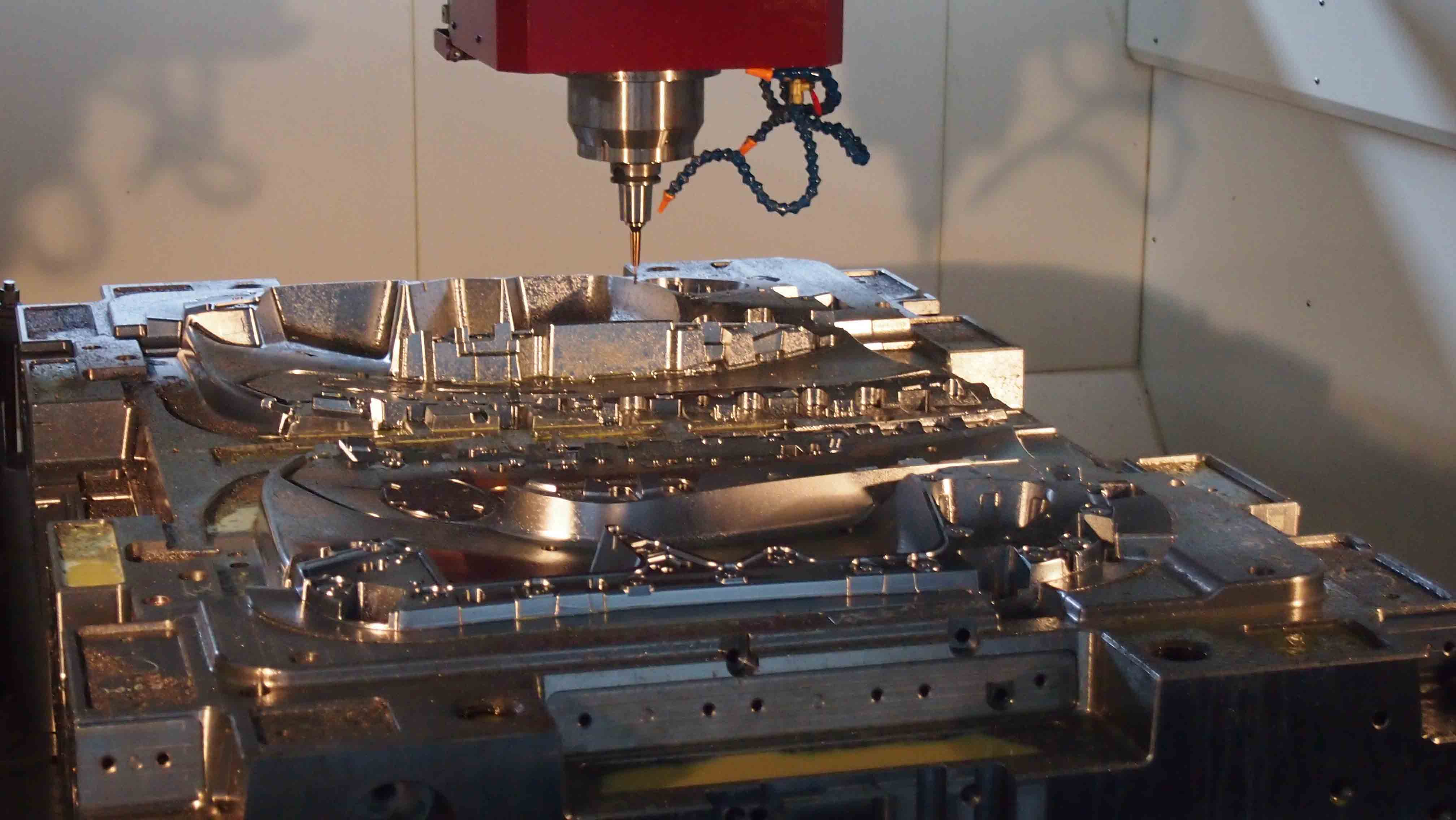

The SMC molding process is to put the sheet plastic into a mould that has been heated to a specified temperature, pressurized by a hydraulic press, so that the molten sheet plastic evenly fills the mold cavity, and then after a period of pressure-holding heating and curing, it becomes an SMC mould. SMC has the advantages of superior electrical properties, corrosion resistance, light weight, easy engineering design, good flexibility, etc. Its mechanical properties can be comparable to some metal materials, so it is widely used in transportation, construction, electronics/electrical, medical, bathroom, etc. industry.

MDC is a very professional SMC supplier. SMC moulds are deeply trusted by customers, involving automotive, industrial, medical, sanitary and other aspects. If you have any SMC mould order requirements, please leave your contact information and we will contact you!

Taizhou Huangyan MDC Mould&Plastic Co.,ltd

No.35-1 Qingfeng Rd, Huangyan North Industrial estate, Taizhou, Zhejiang, china 318020

E-mail:[email protected];

Website: compression mould