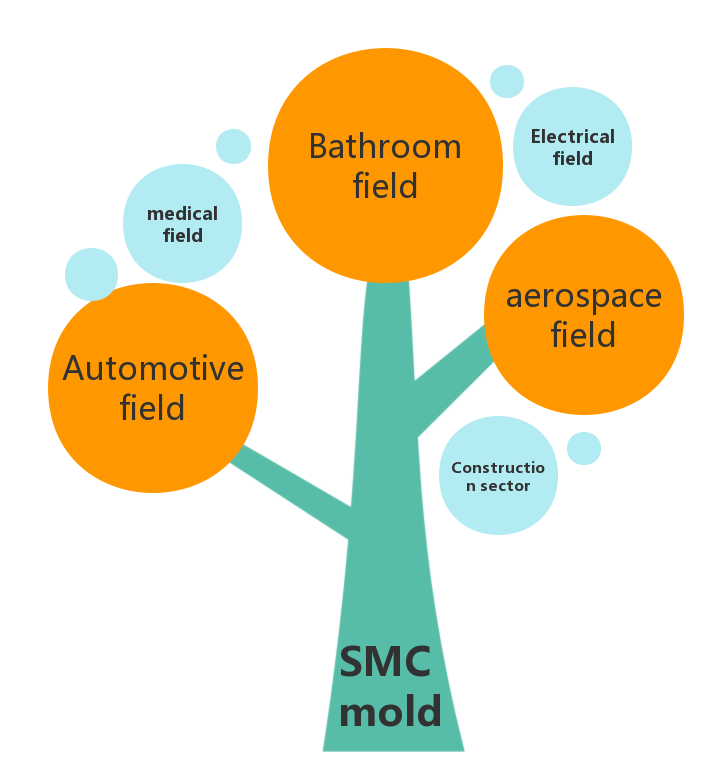

Introduction to Tooling in Compression Molding

In the context of compression molding, tooling refers to the molds and related equipment used to shape raw materials into finished products. The tooling process involves designing, manufacturing, and maintaining these molds to ensure they produce parts that meet specified dimensions and quality standards. Tooling is crucial because it directly influences the accuracy, consistency, and efficiency of the molding process.

Components of Compression Molding Tooling

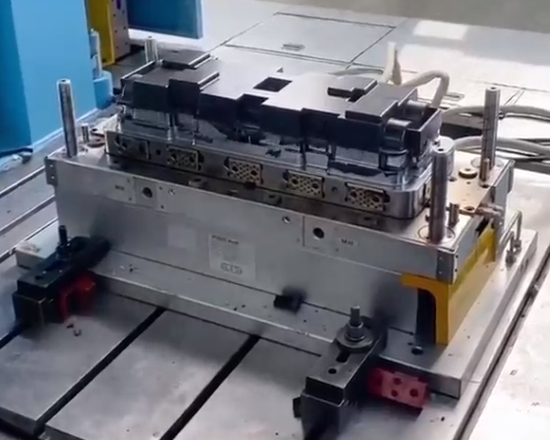

Molds

Molds are the primary components of tooling, designed to shape the material into the desired form. Molds can be single-cavity or multi-cavity, depending on the production volume and part complexity. Common materials for molds include steel and aluminum, chosen based on factors like durability, cost, and the type of material being molded.

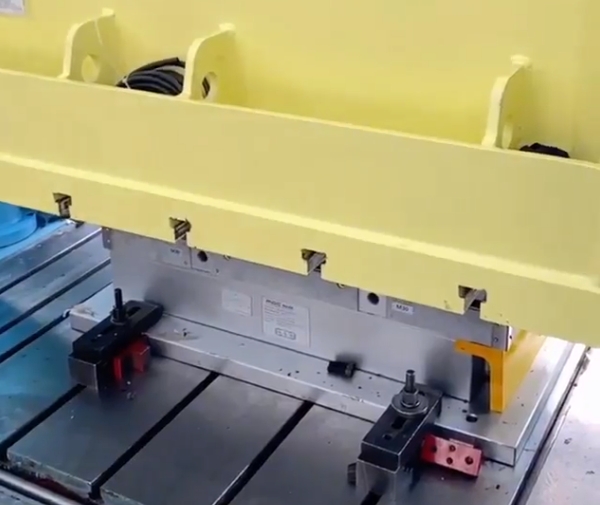

Plates

Top and bottom plates enclose the mold and apply the necessary pressure to shape the material. Ejector plates are used to eject the finished part from the mold after the molding cycle is complete.

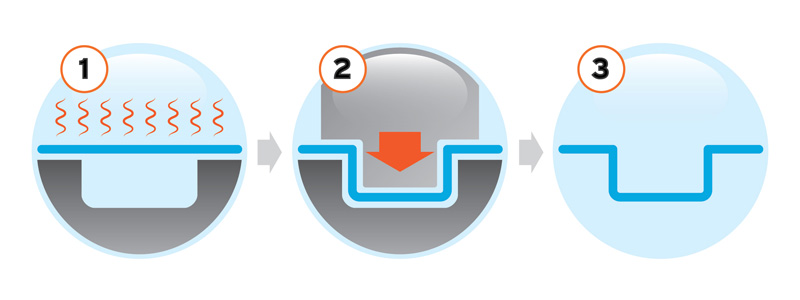

Heating Elements

Heating elements are integrated into the mold to maintain the required temperature for curing the material. Common types include electric heaters and oil or steam heating systems.

Cooling Systems

Cooling systems help control the temperature of the mold, ensuring the material solidifies correctly. Water channels and air cooling are commonly used methods.

Types of Tooling in Compression Molding

Prototype Tooling

Prototype tooling is used for testing and validating new designs before full-scale production. These molds are typically made from less expensive materials like aluminum to reduce costs.

Production Tooling

Production tooling is used for large-scale manufacturing of final products. These molds are made from durable materials like hardened steel to withstand high volumes and repeated use.

Family Tooling

Family tooling is designed to produce multiple different parts simultaneously. These molds contain multiple cavities, each shaped differently to produce various parts in one molding cycle.

Importance of Tooling in Compression Molding

Precision and Accuracy

High-quality tooling ensures that parts are produced with precise dimensions and tight tolerances. This reduces the need for secondary operations like machining or finishing.

Efficiency and Productivity

Well-designed tooling minimizes cycle times and increases production throughput. This enhances overall manufacturing efficiency and reduces operational costs.

Quality and Consistency

Consistent mold quality ensures that each part produced meets the required standards. This improves product reliability and customer satisfaction.

Cost-Effectiveness

Investing in high-quality tooling can reduce long-term costs associated with maintenance and part defects. This provides a better return on investment over the tooling’s lifespan.

Design Considerations for Compression Molding Tooling

Material Selection

The choice of mold material depends on factors such as the type of material being molded, production volume, and budget. Common materials include steel for high durability and aluminum for cost-effective prototyping.

Mold Design

The design must accommodate the complexity of the part, including features like undercuts and intricate shapes. Using computer-aided design (CAD) and simulation tools can optimize the mold design and predict potential issues.

Temperature Control

Effective temperature control systems are essential for maintaining consistent mold temperatures and ensuring proper material curing. Heating and cooling elements must be integrated into the mold design to optimize performance.

Maintenance and Longevity

Regular maintenance is necessary to extend the lifespan of the tooling and maintain part quality. This includes cleaning, inspection, and timely repairs to prevent defects and production downtime.

Challenges in Tooling for Compression Molding

Design Complexity

Designing molds for complex parts can be challenging and time-consuming. Utilizing advanced CAD software and simulation tools can help refine designs.

Cost Considerations

High initial costs for tooling can be a barrier for small manufacturers. Balancing upfront investment with long-term cost savings through efficient production and reduced defects is crucial.

Material Compatibility

Ensuring the mold material is compatible with the molding material to prevent wear and defects is important. Selecting appropriate mold materials and coatings can enhance durability.

Temperature Management

Maintaining consistent mold temperatures can be challenging, especially for large or complex molds. Implementing advanced heating and cooling systems can ensure uniform temperature distribution.

Conclusion

Tooling in compression molding is a pivotal aspect that determines the success of the molding process. From the initial design and material selection to temperature control and maintenance, every element plays a crucial role in producing high-quality, consistent parts. Understanding the importance of tooling and addressing the associated challenges can lead to significant improvements in manufacturing efficiency, product quality, and cost-effectiveness.

By investing in high-quality tooling and employing best practices in design and maintenance, manufacturers can optimize their compression molding operations and achieve superior results. Whether for prototype development or full-scale production, tooling remains a cornerstone of successful compression molding, driving innovation and excellence in the manufacturing industry.