MDC Mould is a renowned manufacturer in the field of SMC (Sheet Molding Compound) molds. In this article, we will explore what SMC material means and its significance in the manufacturing industry.

SMC material is a type of composite material that combines various components to create a unique composite with exceptional properties. It is composed of four main constituents: thermosetting resin, chopped glass fibers, fillers, and additives.

Thermosetting resin acts as the matrix of the SMC material. Polyester, vinyl ester, and epoxy resins are commonly used in SMC manufacturing. These resins offer excellent heat resistance, mechanical strength, and chemical stability, making them suitable for a wide range of applications.

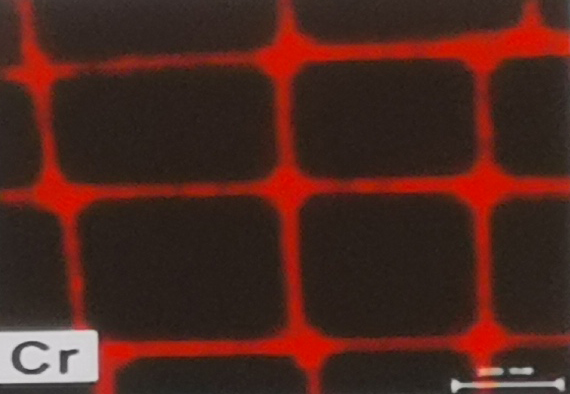

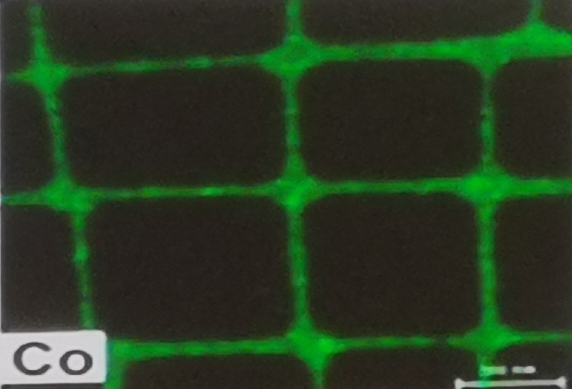

Chopped glass fibers are an essential component of SMC material. These fibers provide reinforcement, enhancing the overall strength and stiffness of the composite. Glass fibers are known for their high tensile strength, impact resistance, and dimensional stability, making them ideal for structural applications.

Fillers are incorporated into the SMC material to modify its properties. Calcium carbonate, talc, or other mineral fillers are commonly used. Fillers help reduce the overall cost, improve dimensional stability, and enhance the surface finish of the final SMC product.

Additives are added to the SMC material to enhance specific characteristics. These additives include colorants, flame retardants, UV stabilizers, and release agents. They contribute to the final properties of the SMC material, such as color consistency, fire resistance, weatherability, and ease of demolding.

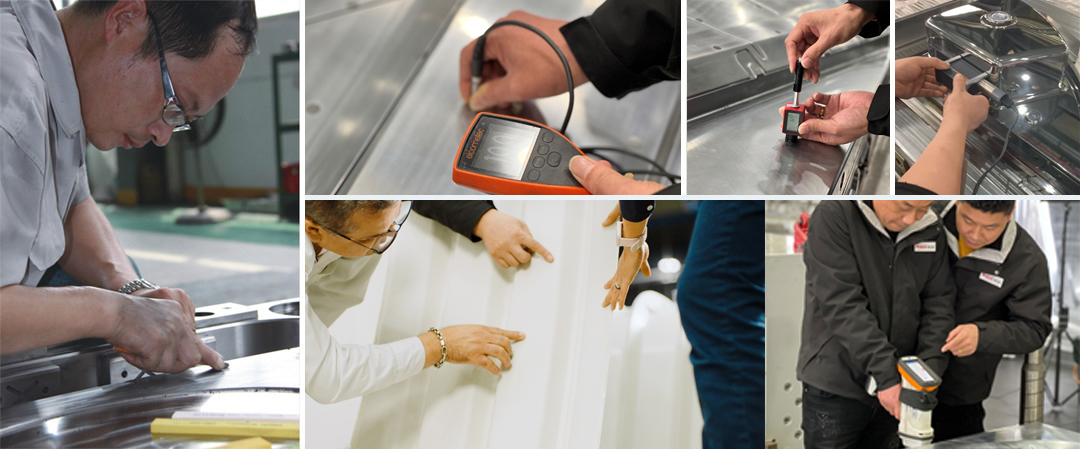

The SMC material manufacturing process involves blending the components together and then compression molding the mixture under heat and pressure. This process allows the resin to cure and bond the fibers and fillers, resulting in a solid, durable composite structure.

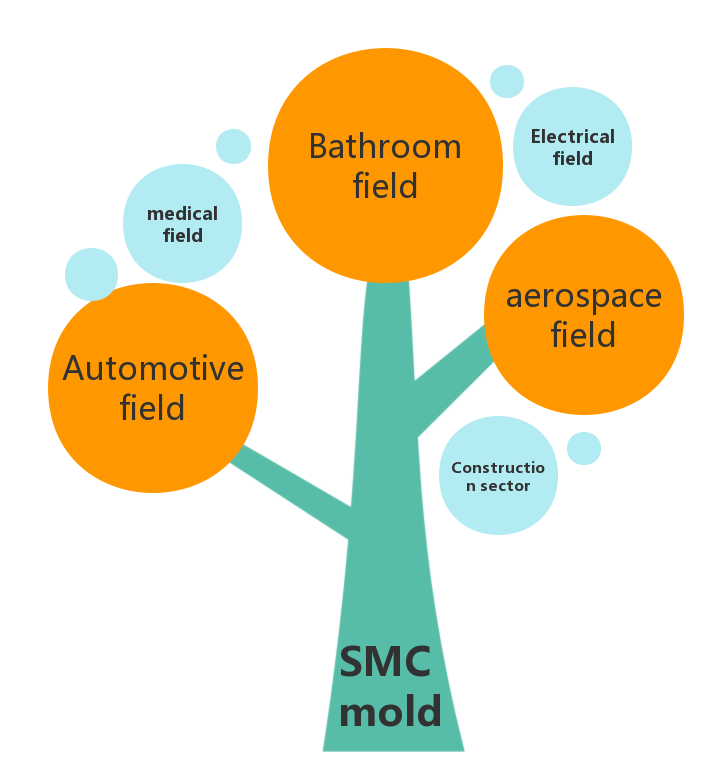

SMC material offers several advantages in the manufacturing industry. Its versatility allows for the production of complex shapes and intricate designs, making it suitable for various industries such as automotive, aerospace, electrical, and construction. SMC parts exhibit excellent mechanical properties, including high strength, dimensional stability, and resistance to corrosion and environmental factors.

MDC Mould, as a leading manufacturer in SMC molds, leverages the unique properties of SMC material to design and produce high-quality molds for a wide range of applications. Their expertise in SMC molding technology enables them to deliver precision, durability, and efficiency in mold manufacturing.

In conclusion, SMC material is a composite material consisting of thermosetting resin, chopped glass fibers, fillers, and additives. It offers exceptional properties, making it a preferred choice in various industries. MDC Mould uses the benefits of SMC material to provide innovative and reliable moulds for a variety of applications, contributing to the advancement of the manufacturing industry.