We will provide you with all the information you need about the uses and benefits of BMC tools in various industries.

Introduction to BMC Tools

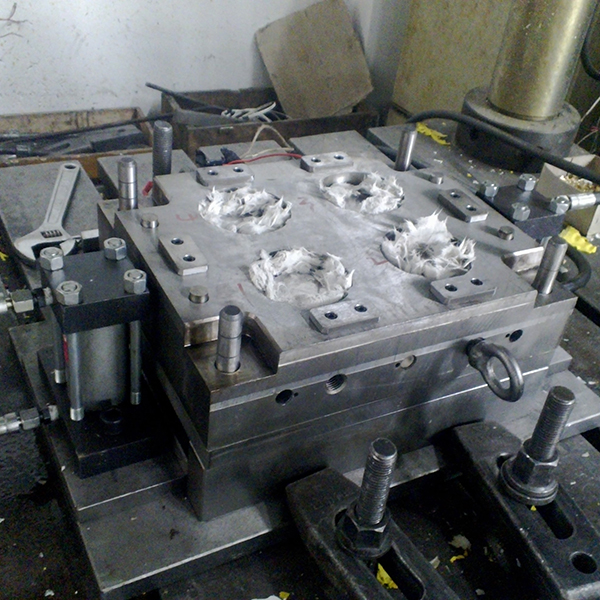

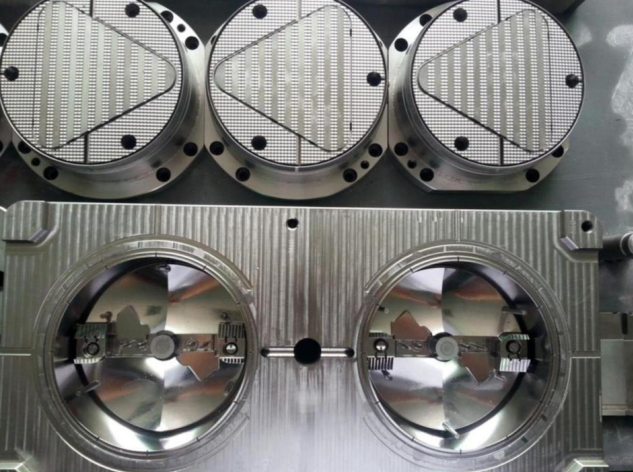

BMC (Bulk Molding Compound) tools are specialized molds used to shape BMC materials into strong and precise components. These tools are engineered to perform under high pressure and high temperature conditions, ensuring efficient production and consistent quality.

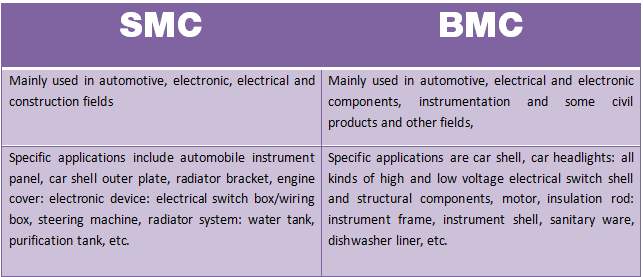

Key Applications of BMC Tools

BMC tools are widely used in many industries where strength, heat resistance, and precision are critical. Here are some of their primary applications:

1. Automotive Industry

BMC tools play a significant role in manufacturing components such as:

- Headlamp Reflectors: These tools help vehicles stay cool and last a long time.

- Engine Covers: These lightweight and heat-resistant parts help vehicles run better.

- Interior Panels: These tools help vehicles look good and work well.

2. Electrical Industry

In the electrical sector, BMC tools help produce components with excellent insulation properties, such as:

- Switchgear Housings: Durable and safe for electrical distribution systems.

- Electrical Connectors: Reliable and precise fittings for power applications.

3. Consumer Goods

BMC tools are used to create high-quality parts for consumer products, including:

- Appliance handles and knobs.

- Structural components for durable goods.

4. Medical Devices

In the medical field, BMC tools help manufacture sterilizable and lightweight components that are essential for healthcare applications.

Advantages of Using BMC Tools

BMC tools offer several benefits that make them indispensable in manufacturing:

- Precision Manufacturing: It ensures high accuracy and consistency.

- Durability: Withstands repeated use under extreme conditions.

- Cost-Effective: Reduces material waste and production costs.

- Versatility: Suitable for producing complex geometries.

- Thermal Resistance: Ideal for high-temperature applications.

The BMC Molding Process

The BMC molding process involves shaping BMC material using compression molding or injection molding techniques. Key steps include:

- Material Placement: The BMC material is placed into the mold cavity.

- Compression: The mold is closed, and the material is heated and pressed into shape.

- Cooling: The part is cooled to solidify its structure.

- Ejection: The finished product is removed from the mold.

Future Trends in BMC Tooling

The need for lightweight, durable, and high-performance components continues to drive advancements in BMC tooling.Here are some of the innovations:

- Improved mold designs for faster cycle times.

- Integration of smart sensors for real-time monitoring.

- Use of advanced materials to extend tool life.

Conclusion

BMC tools are critical in manufacturing a wide range of components with superior mechanical and thermal properties.Their versatility and efficiency make them essential to modern industries such as automotive, electrical, and consumer goods. If you need expert guidance and high-quality solutions, consider partnering with experienced manufacturers like MDC Mould.