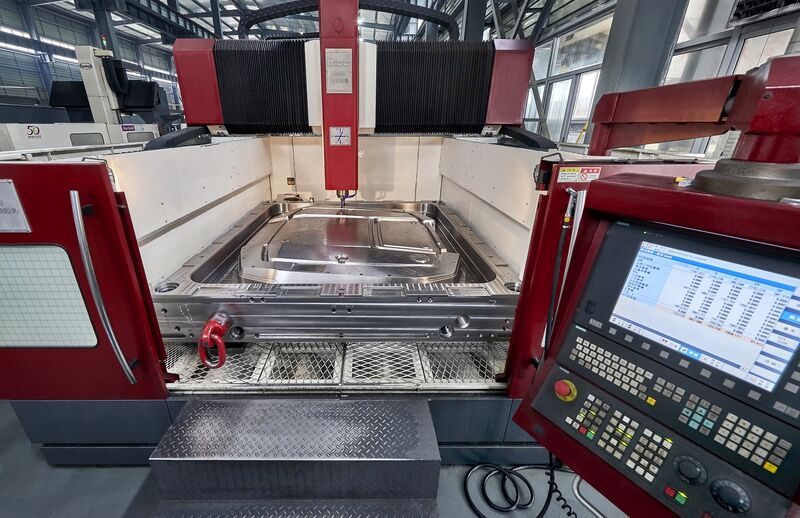

MDC Mould, a trailblazing name in the field of manufacturing, development, and creation, is excited to announce a significant expansion of our production capabilities. In our unwavering commitment to delivering top-quality molds, we have made strategic investments in cutting-edge high-speed milling machines.

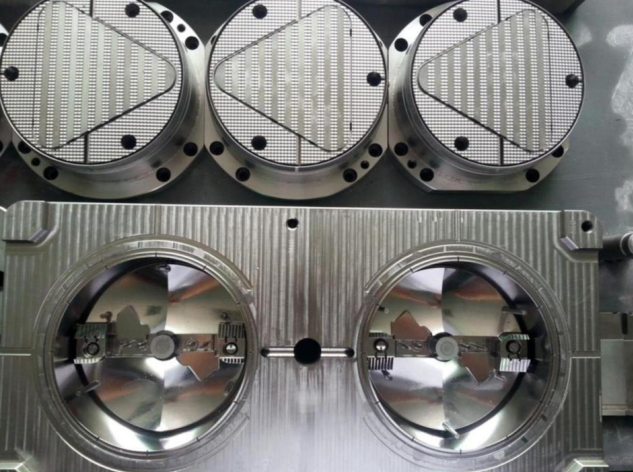

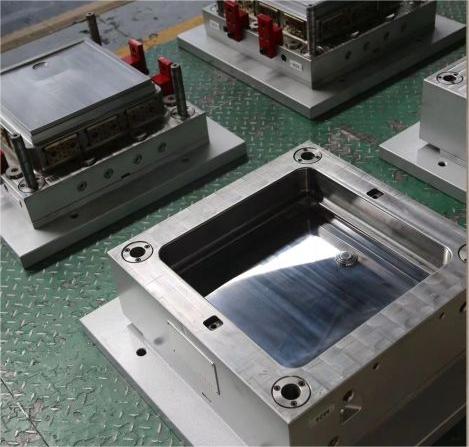

These state-of-the-art machines, boasting an impressive bed size, mark a substantial step forward in our mission to cater to the ever-growing needs of the composite industry. With the ability to produce larger and more intricate tools, we are now even better equipped to meet the demands of our valued customers.

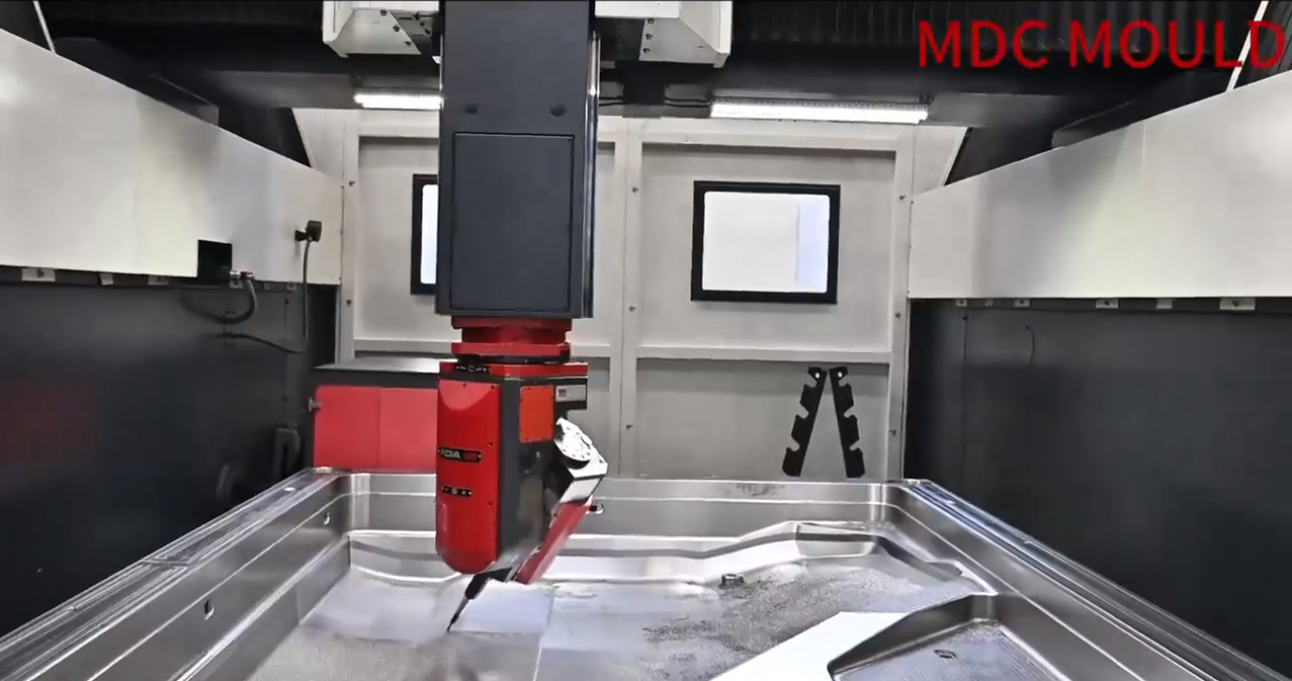

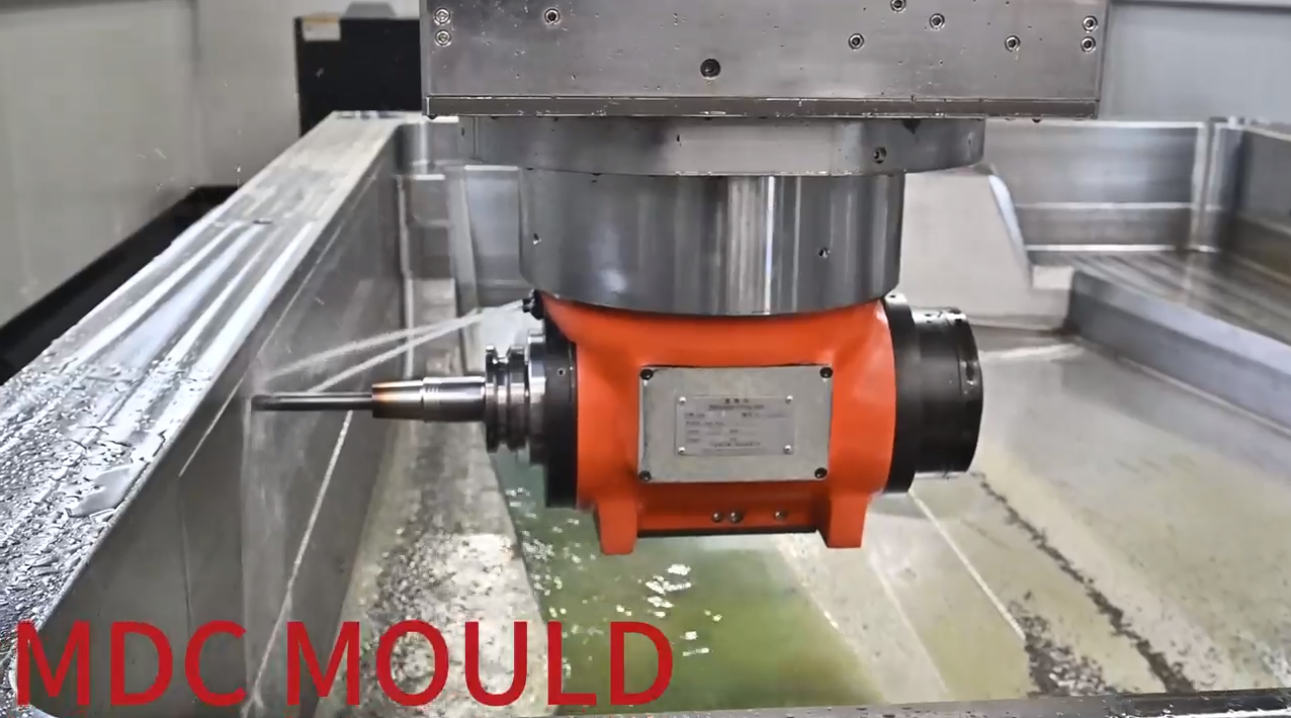

1. Unmatched Precision: The high-speed milling machine, equipped with advanced CNC technology, ensures unparalleled precision in crafting SMC moulds. This precision is essential in delivering flawless finished products.

2. Increased Productivity: With its high-speed capabilities, the machine significantly reduces production times, allowing for faster turnaround without compromising on quality.

3. Versatility: The large bed size of the milling machine accommodates a wide range of mould sizes and complexities, making it an ideal choice for diverse SMC moulding needs.

4. Improved Surface Finish: The machine’s high-speed spindle and cutting-edge tooling result in improved surface finish, which is crucial for SMC moulds that require high levels of detailing.

MDC Mould’s investment in this high-speed milling machine is a testament to the company’s unwavering commitment to providing top-tier solutions to its clients in various industries, including automotive, aerospace, and beyond. This innovative addition aligns seamlessly with MDC’s ethos of Manufacture, Development, and Creation, as it signifies a significant leap forward in the creation of advanced SMC moulds.

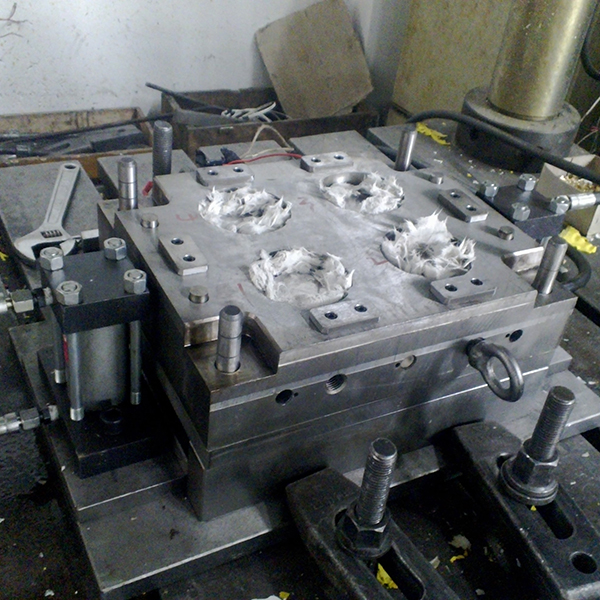

At MDC Mould, we take great pride in being a leader in compression mould production. Our continued dedication to excellence in craftsmanship and precision has driven us to invest in these advanced milling machines. This advancement empowers us to provide an even higher level of quality and efficiency in our mould production processes.

As we move forward, our promise remains unwavering: to offer the best service and provide professional SMC Mould that surpass industry standards. We are poised for a future of innovation and excellence, ensuring that our customers receive the finest solutions for their composite needs.

This investment in high-speed milling machines is a testament to our commitment to exceeding our customers’ expectations and solidifying MDC Mould’s reputation as a leading force in the manufacturing and development industry. We look forward to embarking on this new chapter and continuing to serve our valued clients with the utmost dedication and expertise.