Carbon fiber layup is a crucial process in composite material manufacturing, widely used in aerospace, automotive, sports equipment, and industrial applications. This article explores various layup techniques, key considerations, and the benefits of using carbon fiber composites.

1. What is the Carbon Fiber Layup Process?

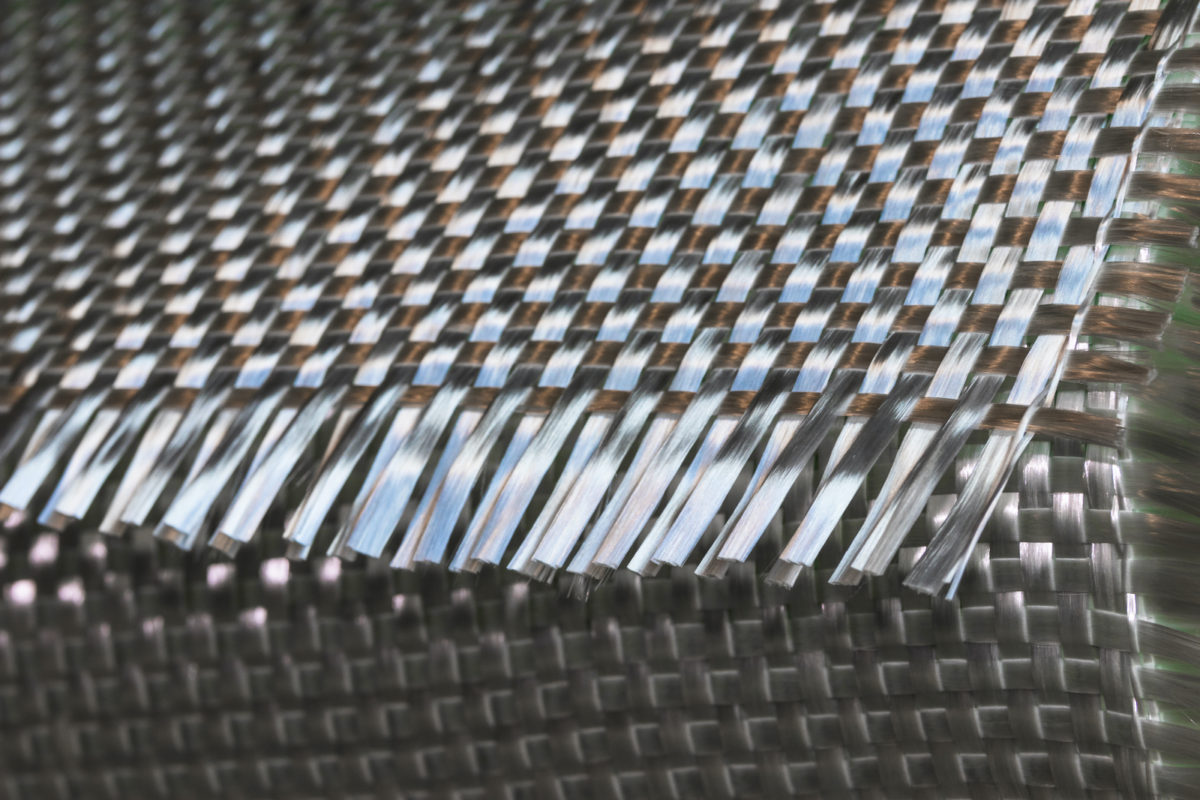

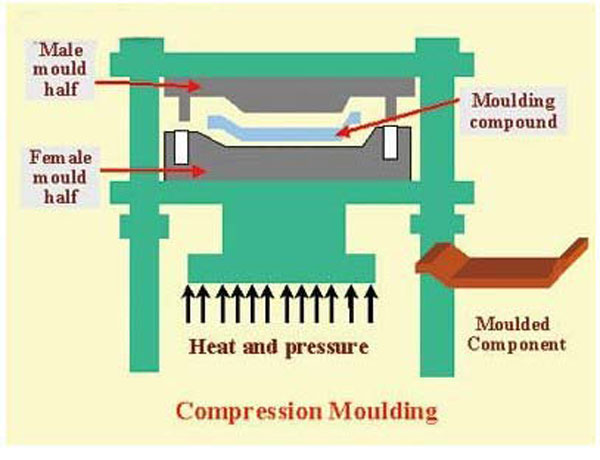

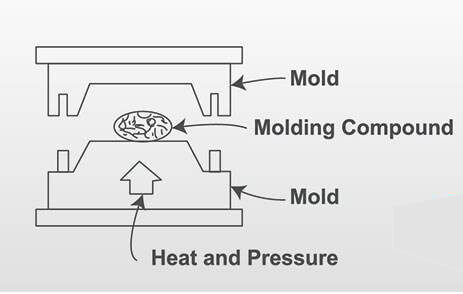

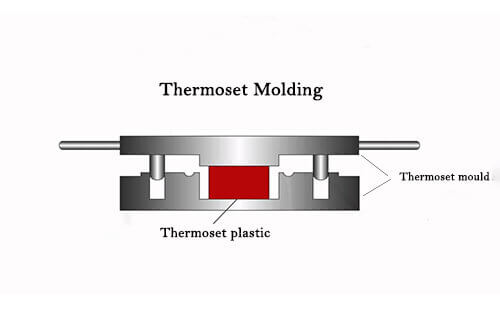

The carbon fiber layup process involves arranging carbon fiber fabrics or preforms in a mold and impregnating them with resin to create high-strength, lightweight composite structures. The process ensures optimal fiber alignment and resin distribution, enhancing mechanical performance.

2. Types of Carbon Fiber Layup Techniques

2.1 Hand Layup

The hand layup technique is a manual process where carbon fiber sheets are positioned in a mold and impregnated with resin. It is cost-effective and widely used for prototyping and low-volume production.

2.2 Vacuum Bagging

Vacuum bagging enhances the hand layup process by applying a vacuum to remove excess resin and air bubbles, improving the composite’s strength and reducing void content.

2.3 Prepreg Layup

Prepreg layup involves using pre-impregnated carbon fiber sheets that contain an exact resin-to-fiber ratio. These sheets require controlled curing conditions, usually in an autoclave, to achieve superior mechanical properties.

2.4 Resin Infusion Process

Also known as Vacuum Assisted Resin Transfer Molding (VARTM), this process draws resin through dry carbon fiber layers using vacuum pressure, ensuring complete wet-out and reducing excess resin.

3. Key Steps in the Carbon Fiber Layup Process

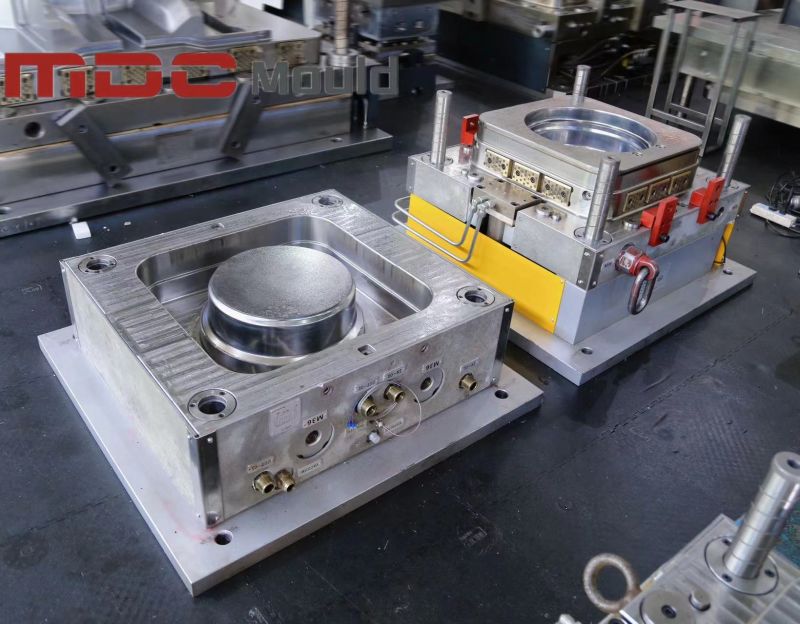

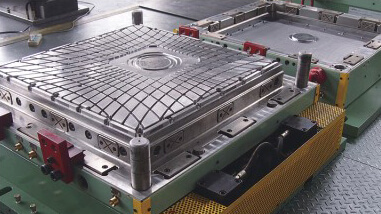

- Mold Preparation: The mold is cleaned, coated with a release agent, and sometimes heated.

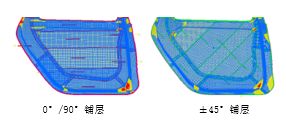

- Fiber Placement: Carbon fiber sheets are carefully positioned according to the required fiber orientation.

- Resin Application: Depending on the method, resin is either manually applied, infused, or pre-impregnated.

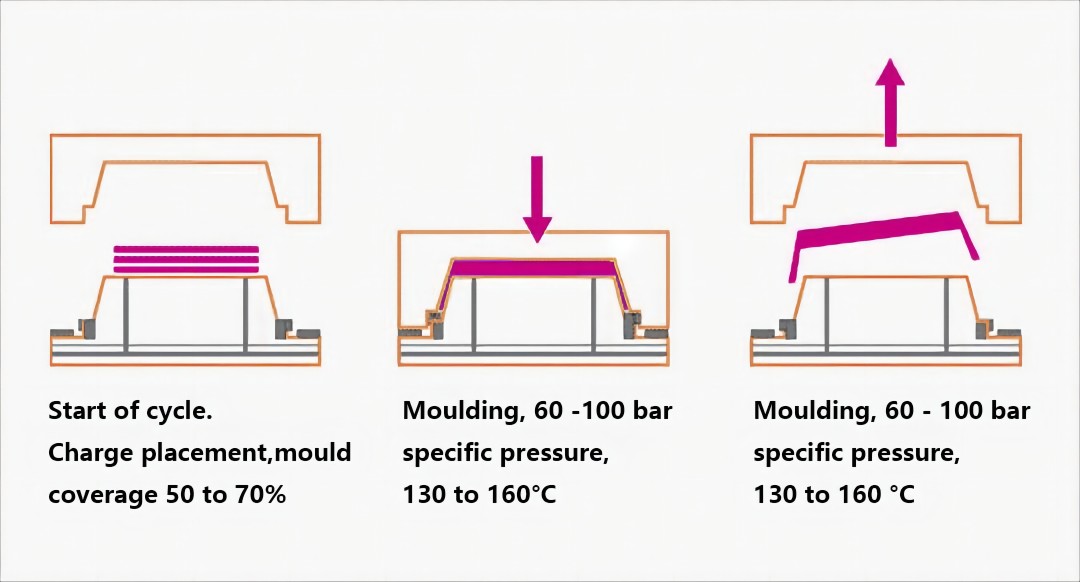

- Compaction: Air bubbles are removed using rollers, vacuum bagging, or autoclave processing.

- Curing: The composite is cured under controlled temperature and pressure conditions.

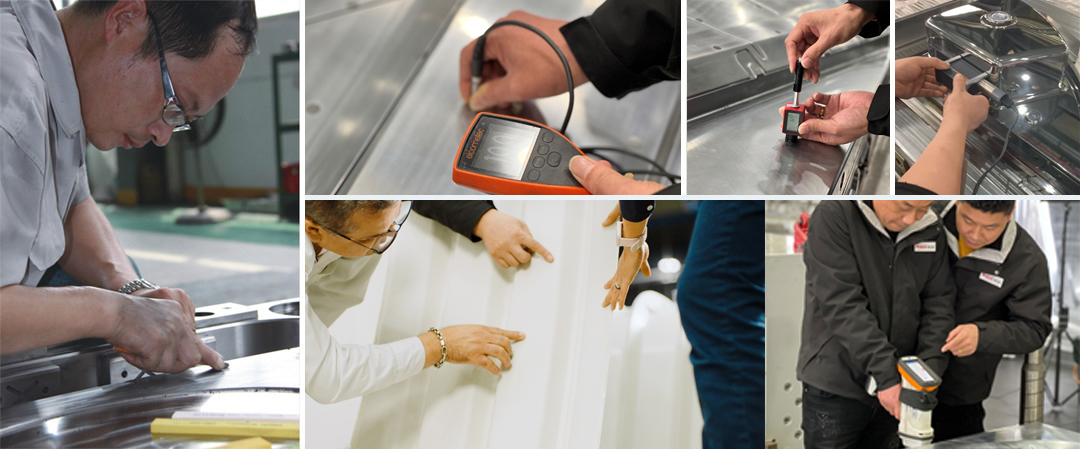

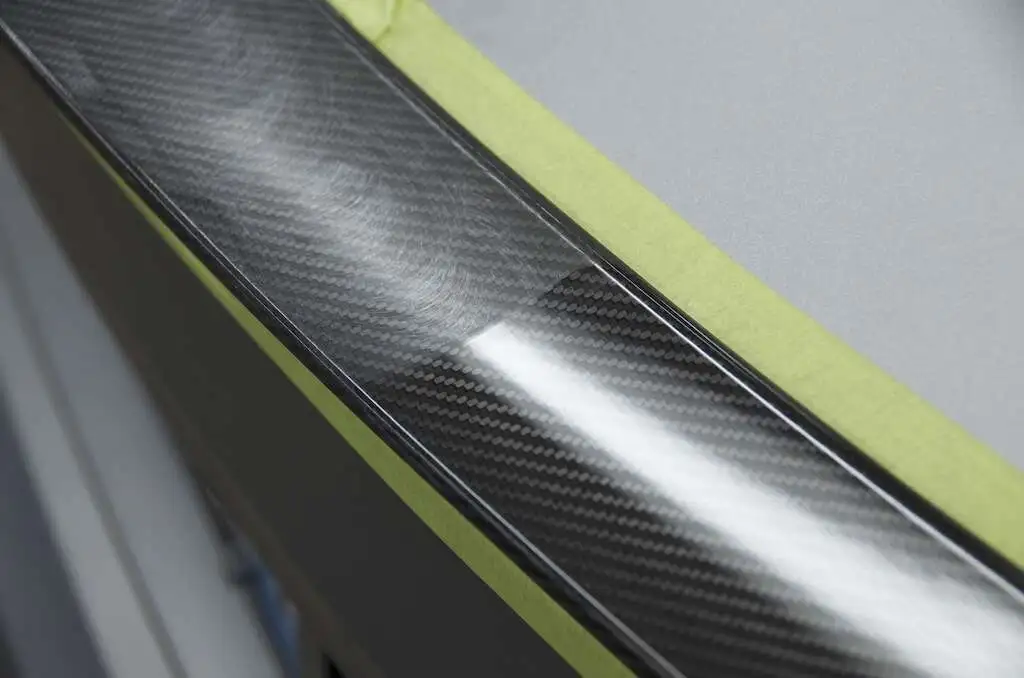

- Finishing: The part is trimmed, polished, and inspected for defects.

4. Applications of Carbon Fiber Layup

4.1 Aerospace Industry

Carbon fiber composites are widely used in aircraft fuselage panels, wings, and interior structures due to their exceptional strength-to-weight ratio.

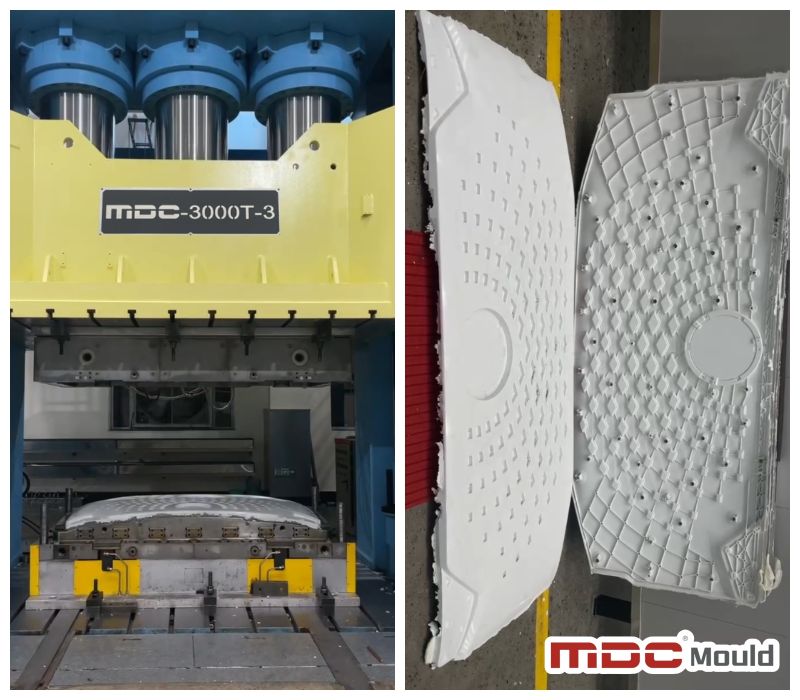

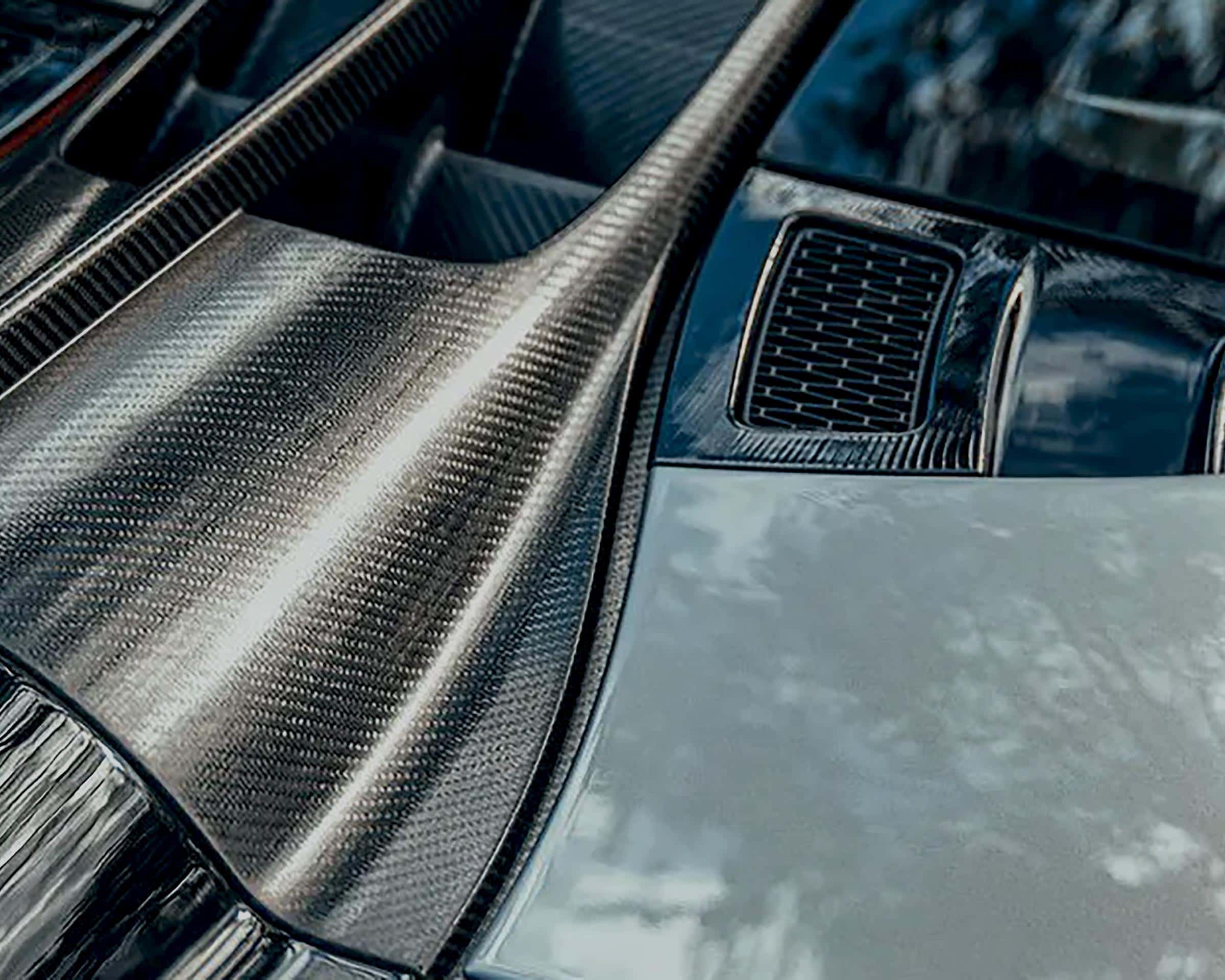

4.2 Automotive Sector

High-performance vehicles use carbon fiber components like hoods, spoilers, and chassis parts to enhance aerodynamics and reduce weight.

4.3 Sports Equipment

Bicycles, tennis rackets, golf clubs, and racing helmets benefit from carbon fiber’s durability and lightweight properties.

4.4 Industrial and Medical Uses

Carbon fiber is used in robotic arms, prosthetics, and wind turbine blades for its high stiffness and corrosion resistance.

5. Advantages of the Carbon Fiber Layup Process

- High Strength-to-Weight Ratio: Carbon fiber composites offer superior strength with minimal weight.

- Corrosion Resistance: Unlike metals, carbon fiber does not rust or degrade in harsh environments.

- Customizable Fiber Orientation: Layup techniques allow optimization for strength, flexibility, and impact resistance.

- Thermal Stability: Carbon fiber composites maintain structural integrity under extreme temperatures.

- Durability and Longevity: Carbon fiber components have a longer lifespan compared to traditional materials.

6. Future Trends in Carbon Fiber Layup

- Automated Layup Systems: Robotics and AI-driven technologies are improving precision and production speed.

- Advancements in Resin Chemistry: New resin systems enhance toughness, recyclability, and fire resistance.

- Expanded Use in Sustainable Solutions: Recyclable carbon fiber materials are gaining traction in eco-friendly manufacturing.

7. Conclusion

The carbon fiber layup process is a cornerstone of composite material fabrication, offering unmatched performance benefits across industries. As advancements in automation, materials, and processing techniques continue, carbon fiber composites will play an even more significant role in lightweight and high-performance engineering solutions.