Carbon fiber parts are in high demand in industries like aerospace and automotive because they’re super strong, durable, and lightweight. This in-depth guide will show you how to mold carbon fiber parts efficiently.

What is Carbon Fiber Molding?

Carbon fiber molding is the process of shaping carbon fiber materials into whatever shape you need. The process is basically about soaking carbon fiber fabric or pre-preg (pre-impregnated) with resin, then letting it set to harden the material. The molding process makes sure that the carbon fiber parts are strong but lightweight, which makes them perfect for lots of different high-performance uses automotive parts, aerospace components, and sports equipment.

Common Carbon Fiber Molding Methods

There are a few different ways to mold carbon fiber parts. Each technique has its own benefits, depending on what you’re using it for, how much you’re making, and what you want the material to be like. Here are the most common ways of molding carbon fiber:

1. Hand Lay-Up Molding

Hand lay-up molding is one of the most popular ways of making carbon fiber parts, especially for custom automotive parts and aerospace structures. This process is all about laying carbon fiber sheets or fabrics into a mold manually, then applying resin. Then the part is cured, either at room temperature or in an oven, to harden the composite.

2. Vacuum Bagging

Vacuum bagging is a more advanced version of the hand lay-up process that ensures better resin infusion and a more uniform thickness. This technique is often used for high-performance carbon fiber parts in industries such as aerospace, automotive, and marine.

3. Resin Transfer Molding (RTM)

Resin Transfer Molding (RTM) is a closed-mold process where resin is injected into a mold cavity containing carbon fiber reinforcement. This method is perfect for making top-quality, high-strength carbon fiber parts used in industries like automotive manufacturing and wind turbine production.

4. Autoclave Molding

Autoclave molding is a high-pressure, high-temperature process that’s mainly used in industries that need the best possible performance, like aerospace. The part is put in an autoclave, where heat and pressure are used to cure the resin and solidify the carbon fiber material.

5. Compression Molding

Compression molding is a popular choice for mass production of high-strength, high-volume carbon fiber automotive parts and consumer goods. In this process, a pre-formed sheet of carbon fiber is placed into a heated mold, where pressure is applied to shape the material.

What makes carbon fiber molding so special?

What makes carbon fiber molding work well? There are a few key things to think about to get the best results.

- Material Selection: The next thing to think about is the material you’re going to use. It’s important to choose the right carbon fiber fabric or pre-preg to get the strength and performance you’re looking for.

- Mold Design: The design of the mold is really important for making sure the resin flows properly, that it’s all the same thickness and that it’s easy to take the mold out.

- Curing Process: If you get the curing right, the resin will fully harden and bond with the carbon fiber to form a solid composite part.

- Quality Control: We do regular quality checks, like visual inspection and mechanical testing, to make sure the parts are up to strength and durability standards.

Where can you find molded carbon fiber parts?

Carbon fiber parts are used in lots of different industries because they’re strong, lightweight and versatile. Here are some common applications:

- Aerospace: In the aerospace industry, carbon fiber is used in everything from aircraft wings and fuselage components to other high-performance parts. Carbon fiber is used in aircraft wings, fuselage components and other high-performance parts.

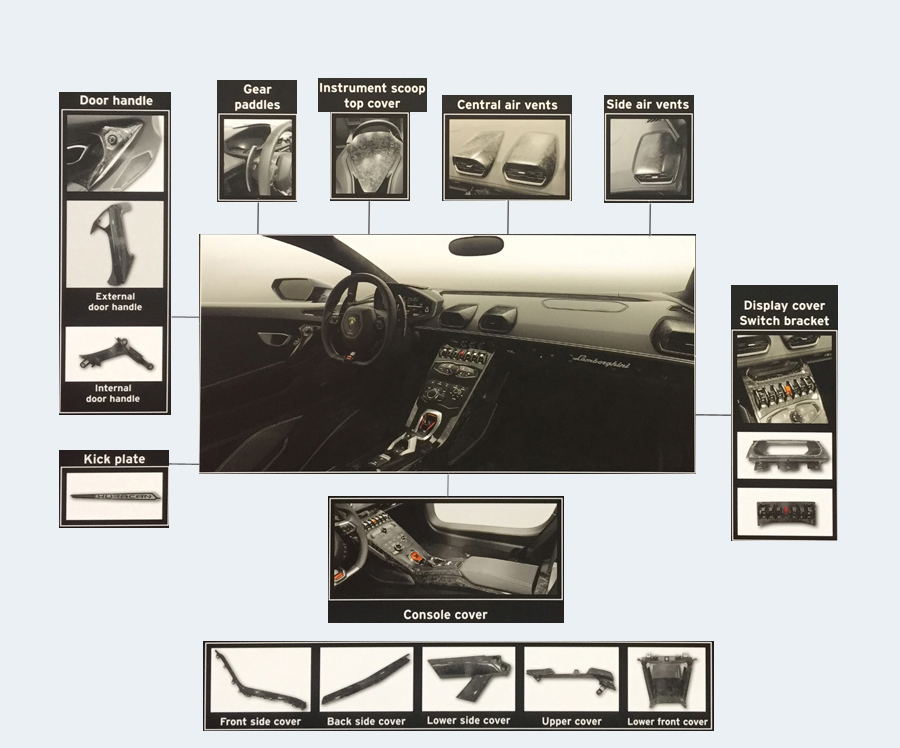

- Automotive: In the automotive industry, carbon fiber is used in things like car bodies, chassis parts and interior components. Using carbon fiber parts like body panels, chassis components and interior elements helps to make vehicles lighter while also making them safer and more fuel-efficient.

- Sports Equipment: Carbon fiber is often used in things like bicycles, tennis rackets and racing boats because it’s really strong and can dampen vibrations.

- Renewable Energy: Carbon fiber molds are used to manufacture durable wind turbine blades and solar panel parts.

Conclusion

Carbon fiber molding is a pretty niche process that produces lightweight, strong and durable parts for all sorts of high-performance applications. If you know which molding technique to use and what the key factors are, you can make carbon fiber parts that meet the demands of industries like automotive, aerospace, and sports equipment. If you’re looking to create high-quality carbon fiber parts, it’s best to consult an experienced manufacturer who can help you get the best results for your specific application.