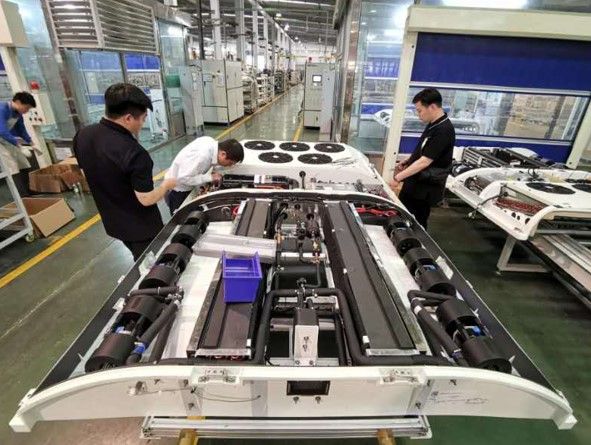

Compression molding is a widely used manufacturing process for producing high-strength, complex shapes from composite materials. Proper mold design is crucial to achieving efficient, high-quality molds with minimal defects. This guide covers essential compression mold design guidelines, including considerations for material selection, mold structure, and processing parameters, to help you create effective molds for a wide range of applications.

Understanding Compression Mold Design

Compression mold design involves creating a mold that applies heat and pressure to mold a material into a specific shape. The mold design affects product quality, cycle time, and the overall efficiency of the molding process. Materials commonly used in compression molding include thermoset polymers like Sheet Molding Compound (SMC), Bulk Molding Compound (BMC), and other reinforced plastics.

Key Guidelines for Compression Mold Design

Compression mold design requires careful attention to several key aspects to ensure optimal performance. Here are some essential guidelines for achieving the best results:

1. Select the Right Material for the Mold

Choosing the correct material for the mold is essential for durability and heat resistance. Common mold materials include P20 steel, hardened steel, and aluminum alloys. Each material offers different levels of wear resistance, cost-effectiveness, and ease of machining:

- P20 Steel: This is a popular choice for compression molds, offering a balance between cost and durability, ideal for medium-volume production.

- Hardened Steel: Known for its durability, hardened steel is best for high-volume production runs but comes at a higher cost and longer machining time.

- Aluminum: Lightweight and easy to machine, aluminum is suitable for prototypes and low-volume runs, though it lacks the wear resistance of steel.

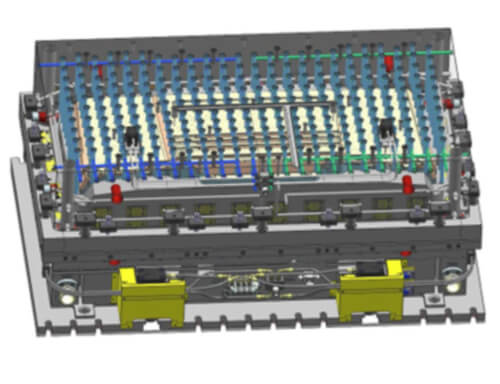

2. Optimize Cavity and Core Design

The cavity and core design of a compression mold directly affect the quality and accuracy of the final product. Key considerations include:

- Wall Thickness: Maintain uniform wall thickness throughout the mold to prevent uneven cooling and warping. Varying thicknesses can cause shrinkage or stress in the molded part.

- Draft Angles: Draft angles facilitate easier demolding, reducing the risk of damaging the product during removal. Typically, a 1-3° draft angle is recommended.

- Rib Design: When adding ribs for structural support, ensure they are designed with adequate thickness and spacing to avoid weak points and stress concentrations in the molded part.

3. Proper Venting and Ejection System

Effective venting is essential to release trapped gases and prevent defects such as voids and burns. Additionally, a reliable ejection system is necessary for easy and safe removal of the molded part. Consider the following tips:

- Venting Channels: Incorporate small venting channels at critical points to allow trapped air to escape during compression, enhancing the overall surface finish.

- Ejector Pins: Strategically place ejector pins to prevent stress marks and ensure uniform release of the part. Ensure the pins are balanced to avoid part deformation.

4. Optimize Heating and Cooling Channels

Efficient temperature control is vital in compression molding to ensure even curing and reduce cycle time. Properly designed heating and cooling channels enhance productivity and part quality:

- Uniform Heating: Ensure the mold heats evenly to avoid hot or cold spots, which can lead to part distortion or inconsistent cure.

- Cooling Channel Layout: Implement a balanced cooling system to manage heat dissipation, minimizing cooling time and preventing warping. Use simulation tools to optimize cooling channel design.

Material Selection for Compression Molding

Material selection is critical to achieving desired performance in compression molding. SMC and BMC are two common types of thermoset materials widely used in compression molds. Here’s an overview of each:

- Sheet Molding Compound (SMC): SMC is a fiber-reinforced thermoset material ideal for applications requiring high strength and durability, such as automotive parts.

- Bulk Molding Compound (BMC): BMC is similar to SMC but is often used for smaller, complex parts. It is highly resistant to moisture and heat, making it suitable for electrical enclosures and similar applications.

Designing for the Compression Molding Process

Compression molding requires molds that can withstand high temperatures and pressures. Here are some additional design tips specific to the compression molding process:

- Press Tonnage: Ensure the mold can withstand the press tonnage used during the compression process. This will prevent deformation and prolong the mold’s life.

- Preheating: Preheat the mold to reduce material flow resistance, improve surface finish, and decrease cycle times. This also helps avoid potential defects caused by rapid temperature changes.

- Compression Ratio: Calculate the appropriate compression ratio to ensure optimal compaction of the material, achieving the desired density and surface finish in the final part.

Common Defects in Compression Molding and How to Prevent Them

Understanding common defects in compression molding and how to prevent them is essential for efficient mold design:

- Porosity: Poor venting can cause air bubbles to get trapped, resulting in porosity. Add adequate venting channels to allow air to escape during molding.

- Warping: Uneven cooling or inconsistent wall thickness can lead to warping. Use balanced cooling channels and ensure uniform wall thickness to minimize this issue.

- Flow Marks: Low mold temperature or insufficient pressure can lead to flow marks. Preheat the mold and ensure the material flows uniformly under sufficient pressure.

Testing and Simulation in Compression Mold Design

Before finalizing a compression mold, testing and simulation can help optimize the design and reduce production issues. Using mold flow analysis software, designers can simulate material flow, temperature distribution, and venting to address potential issues before production.

- Finite Element Analysis (FEA): FEA allows you to analyze stress distribution within the mold to prevent early failure and ensure durability.

- Mold Flow Simulation: This technique simulates the flow of material into the mold, helping identify and address issues with venting, fill patterns, and pressure.

Conclusion

Compression mold design is a complex but rewarding process that requires careful attention to materials, temperature control, and structural design. By following these guidelines, manufacturers can produce molds that deliver consistent, high-quality results for various applications. From material selection to venting and ejection, each aspect of mold design influences performance and durability. For anyone involved in compression molding, adhering to these guidelines will help maximize production efficiency, reduce defects, and extend the life of the mold.

For more information about compression mold design and manufacturing solutions, contact our team of experts. We provide guidance, tooling solutions, and support for all aspects of compression molding.