The quality of woven carbon fiber fabric/polycarbonate thermoplastic composites after thermoforming and demolding has been a subject of considerable research, especially for applications in industries that require SMC molds and composite molding. These composites are critical in sectors utilizing compression molds and carbon fiber molds.

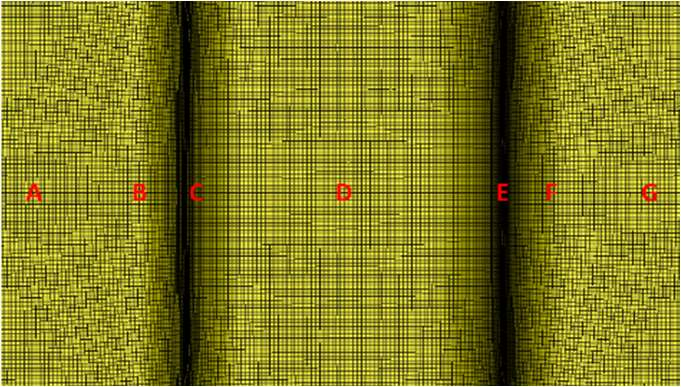

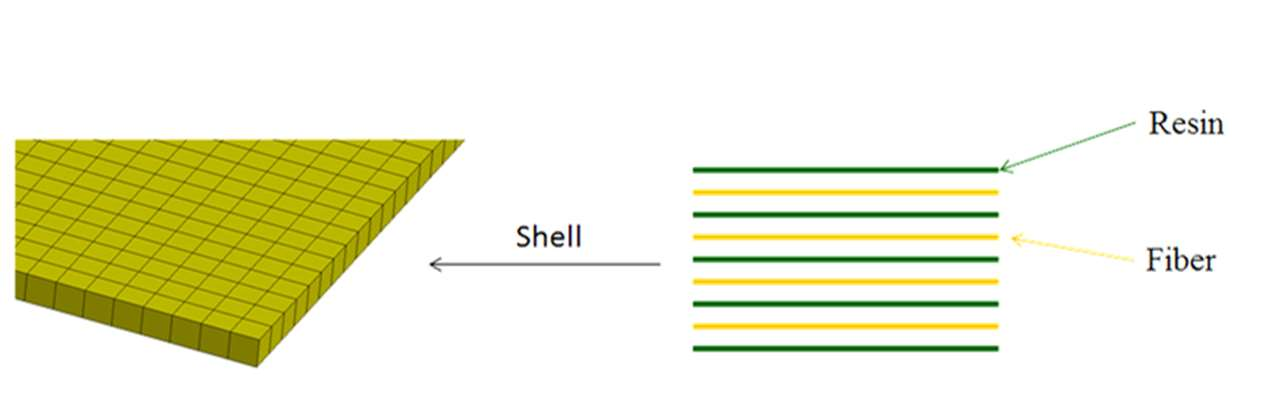

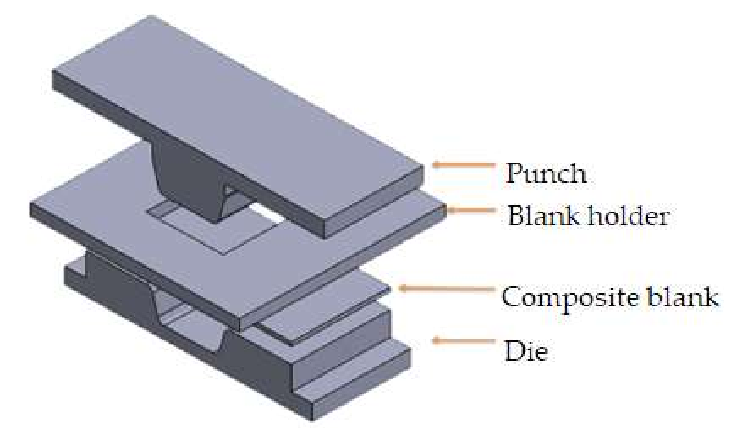

This study investigates the effects of thermoforming parameters using a combination of finite element simulation and the Taguchi orthogonal array. The simulation model employed a discrete approach with a micro-mechanical model to describe the deformation behavior of the woven carbon fiber fabric, similar to what is seen in thermoforming molds and compression tooling. In parallel, a resin model was incorporated to ensure accurate simulations. This approach was validated through bias extension tests conducted at five different temperatures, providing essential data on material behavior during the thermoforming process, much like processes involving BMC molds and press molds.

Key Thermoforming Parameters

The study focused on three key thermoforming parameters, each having three levels, similar to those considered in compression molding:

- Blank Temperature: Influences the material’s flexibility and ability to conform to mold shapes, crucial in SMC tooling and BMC molding.

- Mold Temperature: Affects the final shape fitness and surface finish of the composite, often impacting thermoforming molds and SymaLITE molds.

- Blank Holding Pressure: Plays a crucial role in keeping the material in place and ensuring consistent molding, essential for composite molds like SMC moulds and carbon fiber molds.

The objective was to optimize four important quality factors: fiber-enclosed angle, spring-back angle, mold shape fitness, and the strain of the U-shaped workpiece, similar to those in thermoset molds and LFT molding. By adjusting the thermoforming parameters, the study aimed to achieve the best combination of these factors across various composite tooling methods.

Results and Analysis

The finite element simulation revealed that the stress-displacement curve obtained from bias extension tests closely matched the simulated results. This verified the reliability of the discrete finite element method used in this study, which has parallels with the validation processes for SMC molding and press tooling.

Moreover, the Taguchi orthogonal array analysis identified blank holding pressure as the dominant process parameter, much like in compression molds and BMC tooling. The optimal value for blank holding pressure was found to be 1.18 kPa, making it the most critical factor in the thermoforming process. Blank temperature was the second most influential factor, with an optimal range of 160°C to 230°C. Interestingly, mold temperature had a relatively minor effect on the final composite quality, similar to the behavior observed in GMT molds and D-LFT molds.

Optimal Thermoforming Settings

The study recommended the following optimal settings for the thermoforming of woven carbon fiber fabric/polycarbonate thermoplastic composites:

- Blank Holding Pressure: 1.18 kPa (critical for compression molds and SMC moulds)

- Blank Temperature: 230°C (relevant for thermoforming tools and hot compression molds)

- Mold Temperature: 190°C (beneficial for composite molding and carbon fiber molds)

These settings resulted in the most favorable outcomes for all four quality factors, indicating that careful control of blank holding pressure and temperature is crucial for achieving high-quality composite molds and thermoforming molds.

Conclusion

In summary, the results of this study provide valuable insights into the effects of thermoforming parameters on woven carbon fiber fabric/polycarbonate thermoplastic composites. The study concluded that blank holding pressure and blank temperature are the two most important factors, with mold temperature playing a secondary role. These findings are essential for those working with composite tooling, thermoforming tools, and compression molds, providing a clear pathway for producing high-quality composites with desirable spring-back angle, fiber-enclosed angle, and mold shape fitness.