Fiber-reinforced polymer (FRP) composite materials are defined as polymers reinforced with fibers, representing a category of materials falling under the broader classification of composite materials. Composite materials are formed by dispersing particles of one or more materials into another material, creating a continuous network around them.

FRP composite materials differ from traditional building materials like steel and aluminum. FRP composite materials are anisotropic, whereas steel and aluminum are isotropic. As a result, their properties are directional, meaning the optimal mechanical performance occurs in the direction of fiber placement.

These materials exhibit a high strength-to-density ratio, excellent corrosion resistance, and convenient electrical, magnetic, and thermal properties. However, their brittleness may impact mechanical performance depending on load rates, temperature, and environmental conditions.

Primary Function of Reinforcement: The primary function of reinforced fibers is to bear loads along the fiber length and provide strength and stiffness in one direction. In many structural applications where load-bearing capacity is crucial, FRP composites have replaced traditional metal materials.

Components of Composite Materials

Fiber:

· Carbon fiber, glass fiber, and aramid fiber are the three main types of fibers used in construction. Composite materials are often named after the reinforcing fiber, for example, CFRP representing carbon fiber-reinforced polymer. The key characteristics between fiber types are stiffness and tensile strain.

Matrix:

· The matrix should transfer forces between fibers and protect fibers from adverse effects. Thermosetting resins (thermoplastics) are predominantly used, with epoxy and vinyl ester resins being the most common matrices.

Applications of Glass Fiber Reinforced Polymer (GFRP):

Glass Fiber Reinforced Polymer (GFRP):

· Formed by melting a mixture of silica, limestone, feldspar, and other minor components.

· Recognized for its high electrical insulation properties, low moisture sensitivity, and high mechanical performance.

· Significant achievements have been made in functionality, safety, and cost-effectiveness in construction.

Applications of Carbon Fiber Reinforced Polymer (CFRP):

Carbon Fiber Reinforced Polymer (CFRP):

· Possesses a high elastic modulus, crucial for applications in prestressed concrete where high corrosion resistance and electromagnetic transparency are essential.

· Used in manufacturing deep-sea pipelines for its significantly increased buoyancy compared to steel.

· Applied in constructing structures requiring electrical neutrality.

Applications of Aramid Fiber Reinforced Polymer (AFRP):

Aramid Fiber Reinforced Polymer (AFRP):

· Aramid is an abbreviation for aromatic polyamide. Well-known trademarks include Kevlar, Twaron, Technora, and SVM.

· Known for high energy absorption, making it suitable for reinforcing engineering structures subjected to dynamic and impact loads.

Future Perspectives:

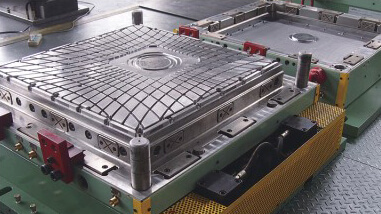

As the demand for sustainable and high-performance materials continues to rise, the application of FRP composite materials in construction, engineering, and manufacturing will expand further. SMC moulds, as critical tools in manufacturing these composite material components, will play a pivotal role in driving future advancements in materials technology.

Sharing this technology across different industries can promote wider adoption of fiber-reinforced polymers, fostering innovation in construction structures, transportation, and other fields. In this ever-evolving field, SMC moulds and fiber-reinforced polymers will collaboratively shape future trends in material development, providing more sustainable solutions for society and the environment.

Ongoing Care Stops Expensive Fixes

Routine roof maintenance can prevent huge and high-priced restorations if neglected untended for lengthy durations. Little damages like leaks, fissures, or missing shingles may turn into significant problems if overlooked. Homeowners must schedule regular checks with licensed roofing contractors to detect any problems early and fix such ahead of they become pricey hassles. Maintaining a roof in top shape can prolong its durability and conserve homeowners costs in the long run.

To demonstrate A dweller notices a small leak in their covering and contacts a qualified professional to inspect. The professional finds several issues that could have caused major destruction if neglected. Resolving these concerns early saves the resident a significant amount of cash in potential repairs.

For the purpose of example An estate holder arranges regular examinations for their covering. In one of these checks, the contractor discovers beginning symptoms of damage. Routine upkeep performed promptly lengthens the durability of the covering and prevents high-priced restorations down the line.

Extensive damage detection and repair near by Leland North Carolina

Avoiding Seaside Corrosion on Your Roofing 3258094