SMC (Sheet Molding Compound) compression moulding is a manufacturing process used to produce composite materials. It involves compressing a pre-prepared mixture of chopped fibers, typically glass or carbon, and a thermosetting resin, such as polyester or epoxy, between two heated moulds to create a finished part.

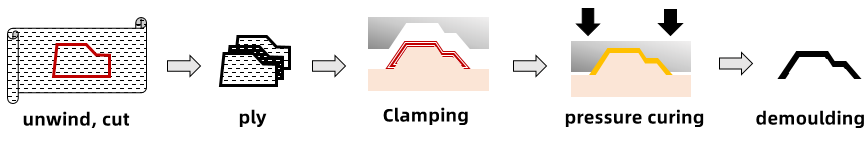

The Process of SMC Compression Moulding:

- Preparing the SMC: Sheet Molding Compound is typically produced by mixing chopped fibers (such as glass or carbon) with a thermosetting resin, along with other additives such as fillers, pigments, and release agents. The mixture is typically in the form of a sheet or a mat.

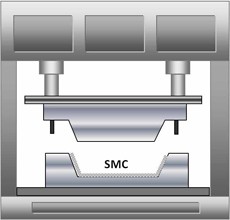

- Placing the SMC in the mould: The SMC sheet is placed in the mould, which is usually made of steel and consists of two halves that can be opened and closed. The mould is typically coated with a release agent to prevent the SMC from sticking to the mould during the curing process.

- Closing the mould: The two halves of the mould are closed, and pressure is applied to compress the SMC sheet. The pressure is typically applied hydraulically and can range from several hundred to several thousand pounds per square inch (psi), depending on the specific material and part requirements.

- Heating and curing: The closed mould, with the compressed SMC, is heated to a specific temperature, typically in the range of 120 to 180 degrees Celsius (250 to 356 degrees Fahrenheit), depending on the resin used. The heat causes the thermosetting resin to cure and harden, forming a solid composite part.

- Cooling and demoulding: After the curing process is complete, the mould is cooled, and the pressure is released. The mould is then opened, and the finished SMC part is demoulded. The part may require additional trimming, drilling, or other post-processing operations to achieve the desired final shape and finish.

As a professional and world-famous mold manufacturer, MDC Mould specialize in SMC mold, compression mold. The company has a skilled and experienced R&D team, as well as a group of high-quality production workers, committed to providing customers with the best quality mold solutions. If you have any need, please feel free to ask us.