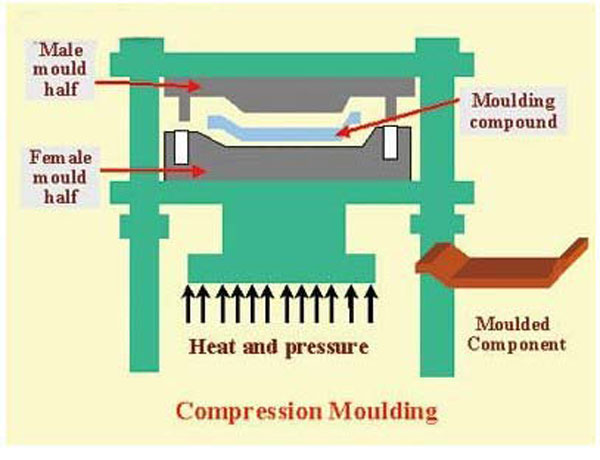

SMC mold(sheet molding compound) is an important manufacturing tool used to produce various composite material products. However, these molds are subject to the risk of wear and damage during the production process, and attention needs to be paid to their maintenance and maintenance to ensure their long-term use, product quality and production efficiency.

Here are some detailed tips on SMC mold maintenance and maintenance:

1. Clean the surface and interior of the mold regularly: Before and after using the SMC mold, the mold needs to be cleaned. First, use air pressure to remove dust and dirt from the surface of the mold. Then, clean the surface and interior of the mold with a specific cleaning agent. Regular cleaning of molds will ensure they remain in top condition and reduce damage and wear from accumulated dirt and impurities.

2. Keep the mold surface lubricated: Proper lubricant can reduce wear and tear on the mold surface and reduce friction. Lubricant should be applied thinly on the surface of the mold to prevent too much lubricant from entering the mold and affecting product quality.

3. Regularly inspect the surface and interior of the mold: Regularly inspect the surface and interior of the mold for cracks, scratches, wear, or other damage. Finding and repairing these problems in time can avoid more serious damage and prolong the service life of the mold.

4. Keep the mold in a dry environment: SMC molds should be stored in a dry and ventilated environment. An environment with high humidity may cause rust and corrosion on the surface of the mold, affecting the service life of the mold.

5. Avoid overloading the mold: When using SMC molds, it is necessary to avoid overloading. Overloading may cause mold deformation, wear and breakage, causing irreversible damage to the mold.

6. Regular replacement of molds: SMC molds also need to be replaced regularly to ensure product quality and production efficiency. The service life of a mold depends on its material, manufacturing process and usage. Mold replacement should be considered when there is visible damage or wear to the mold surface, or when the product begins to change in size and shape.

In short, the maintenance and maintenance of SMC molds is an important measure to ensure the normal operation of the mold and prolong its service life. Regular cleaning, lubrication and inspection of molds, as well as avoiding overloading, can ensure the normal operation and efficient production of molds. Maintaining and maintaining molds can help companies reduce production costs, improve product quality, and ensure the safety of the manufacturing process.

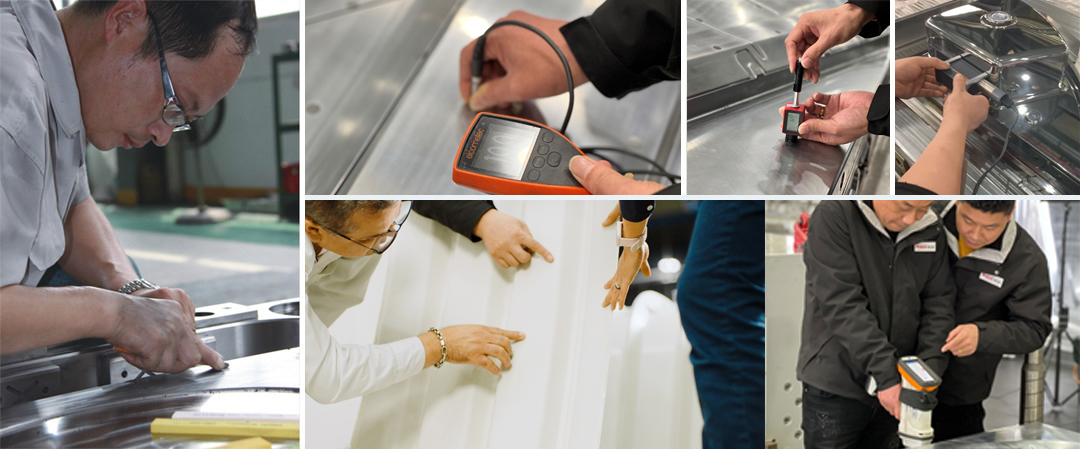

MDC Mould is a professional mould manufacturer, especially of SMC molds.The molds developed by our company have short (2-4 minutes) cycle time and the use of machined tool steel molds supports a program volume of more than 500,000 units per year. Our company adheres to the concept of professionalism and integrity, and will focus on developing higher-quality, higher-tech molded FRP molds in the future.

Our molds not only have high difficulty, long service life and short cycle time, but also have reasonable price, timely delivery and considerate service, which are favored by customers at home and abroad. If you have any needs, welcome to contact us.