Carbon fiber composite materials are composed of composite materials such as carbon fibers and resins, and have the advantages of light weight, high strength, good rigidity, and corrosion resistance. Due to these characteristics, carbon fiber composite materials have been widely used in aviation, automobiles, sporting goods, construction and other fields.

In the automotive industry, carbon fiber composite products can replace traditional steel and aluminum products, which can reduce vehicle weight and improve fuel efficiency and vehicle performance. In the field of aviation, carbon fiber composite products can also reduce the weight of aircraft, improve fuel efficiency and flight performance. At the same time, carbon fiber composite materials are also widely used in sporting goods, such as golf clubs, bicycles, skateboards, etc., because of their light weight and good strength, they can improve the performance of athletes.

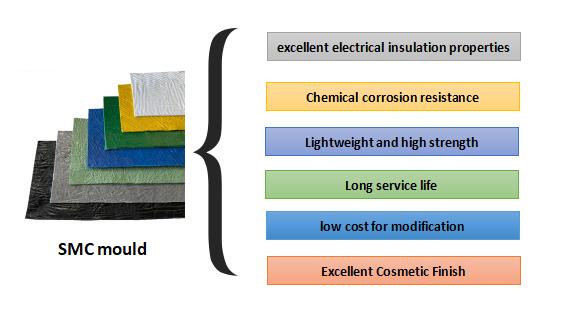

The SMC mold adopts the “SMC compression molding processing” production process. SMC, or Sheet Molding Compound, is a prefabricated composite material, usually composed of carbon fibers, resins, fillers, and additives.

The use of SMC molds in the production of carbon fiber composite materials offers several advantages over other manufacturing methods. These advantages include:

1. High precision and accuracy: SMC molds allow for the production of high-precision, high-quality carbon fiber composite products with consistent dimensions and shapes. This ensures that the final products are of the highest quality and are highly accurate.

2. High production efficiency: SMC molds can be used to mass-produce carbon fiber composite products with high efficiency. This can significantly reduce production costs and increase productivity.

3. High-quality finish: Carbon fiber composite products manufactured using SMC molds have a smooth, high-quality finish. This reduces the risk of deformation and cracking and ensures the durability and stability of the final product.

4. Design flexibility: SMC molds can be customized to meet specific design requirements, enabling the production of carbon fiber composite products of different shapes and sizes.

In conclusion, the use of SMC molds in the production of carbon fiber composite materials is a highly efficient, accurate, and cost-effective method. As carbon fiber composite materials become increasingly popular in a wide range of industries, the importance of SMC molds will only continue to grow. Future advancements in SMC mold manufacturing technology will undoubtedly lead to even more efficient, accurate, and high-quality production of carbon fiber composite materials.

MDC Mould focuses on composite material molds and compression molds, and is a very professional and well-known SMC mold manufacturer at home and abroad. The company has mature and complete development capabilities. As a local manufacturer of hot-pressing molds in China, the molds manufactured by the company can fully meet the quality requirements of the world’s top 500 companies, and its technology has reached the international level.