In 2022, the world is still under the influence of the epidemic, and many industries are swaying in the wind and rain. Even if the economic conditions are down, there is one industry in the world that is growing rapidly, which is new energy vehicles. As consumers’ demands for environmental protection, energy saving, and intelligence continue to increase, new energy vehicles are the future development trend of the automotive industry. But while environmental benefits are a motivating factor for EV adoption, vehicle performance and technology are the main draw. The improved driving experience brought about by technological progress, design and styles are all key factors in the popularity of electric vehicles. Especially for ordinary people, the most important advantage of new energy vehicles is not environmental protection, but low travel costs, and electricity bills are much cheaper than fuel bills.

Compared with traditional metal materials, composite materials manufactured by SMC molds(sheet molding compound) have the following advantages:

1. Lightweight: Composite materials made by SMC molds are lighter than metal materials, which helps to reduce the weight of the vehicle and improve the mileage and energy-saving effect of new energy vehicles.

2. High strength: The composite material made by SMC mold has high strength and rigidity, which can improve the impact resistance and tensile resistance of the body, and improve the safety of the vehicle.

3. Corrosion resistance: The composite material made by SMC mold is not easy to be corroded, which can ensure the long-term stability of the body and components.

4. Good shapeability: SMC molds can produce complex body and component shapes, have better shape performance, and can meet the design requirements of new energy vehicles.

5. SMC molds can also realize automated production through digital manufacturing technology, improve production efficiency and quality, and realize intelligent manufacturing, which will help promote the modernization and intelligence of new energy vehicle manufacturing.

Therefore, SMC mold provides important support and solutions for the manufacture and development of new energy vehicles.

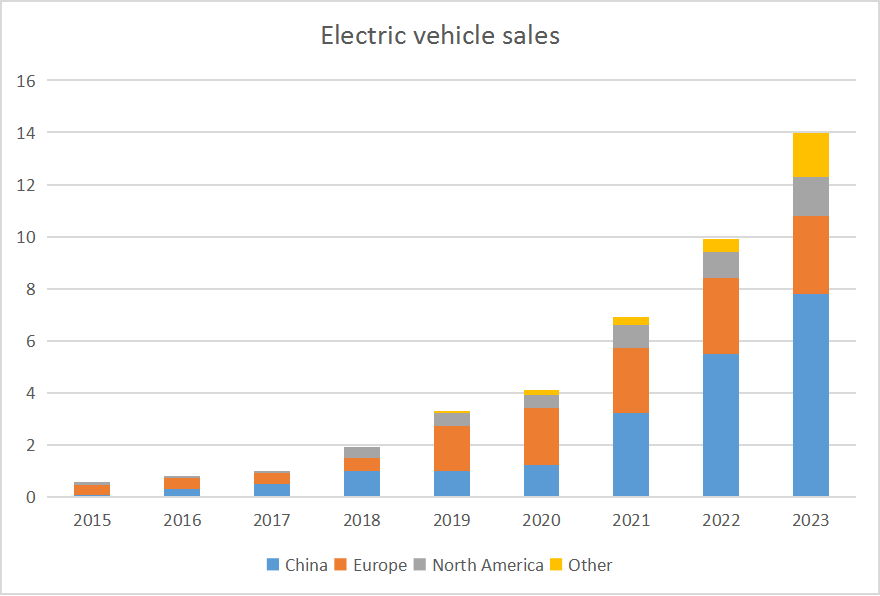

According to the statistics, China is already the world’s largest market for electric vehicles, and it also leads in terms of infrastructure. There is no doubt that China is ahead of the trend.

MDC Mould is a professional manufacturer of SMC mold and BMC mold. The molds developed by our company have high difficulty, long service life, short cycle time, reasonable price, prompt delivery and considerate service, and are favored by customers at home and abroad.

warfarin 2mg usa – order metoclopramide 20mg sale oral losartan 50mg