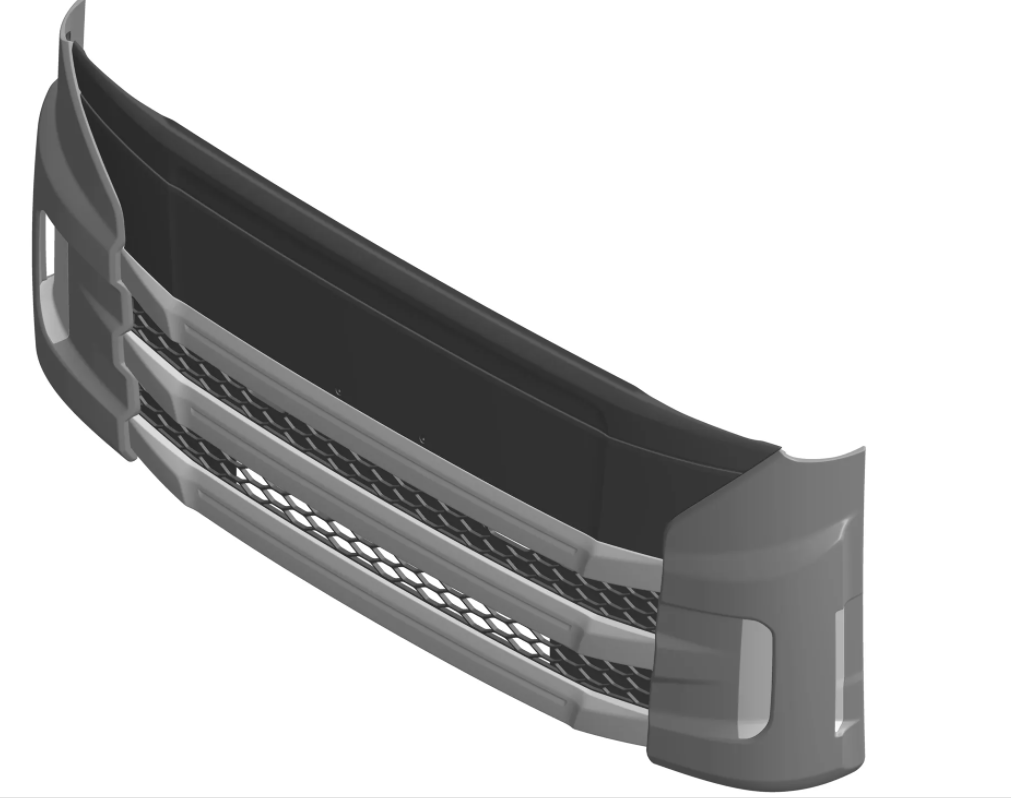

In this issue, let’s explore the reason why the front cover of the car adopts SMC mould.

The front cover of a car is an indispensable part of every car, but the material used is also very particular. Now on the market, more and more car front covers are made of SMC materials, so why can the front cover mold stand out? Let’s analyze it.

①Light weight of the front mask mold: Comparing with steel materials, composite materials can reduce the weight by 20-30%, but the stiffness and strength are similar, so people will naturally choose lighter weight.

②Excellent physical properties of the front mask mold: the mold material can maintain good strength and rigidity even under high temperature conditions, which can basically compete with aluminum alloy materials, and is an ideal material for replacing steel with plastic.

③Corrosion resistance of the front mask mold: SMC material itself is a corrosion-resistant material. At the same time, when this material is hit by an external force, the ability to rebound from the dents or depressions produced is stronger than steel.

④The front mask mold has heat resistance: this SMC material can maintain dimensional stability from -50 degrees Celsius to +200 degrees Celsius.

To sum up, there are reasons why SMC front mask are becoming more and more popular materials.

MDC Mould has rich experience in the production of SMC moulds. As a supplier of SMC moulds, it has many years of research in the design of SMC moulds and mold technology. Mass production to meet customer needs. If necessary, please contact us!